Overview

This article presents ten key benefits of ball bearing fans specifically tailored for electronics engineers. It highlights their superior performance, energy efficiency, and longevity in comparison to traditional fan designs. Supported by evidence, these advantages include:

- An extended lifespan

- Reduced maintenance requirements

- Enhanced operational efficiency

Consequently, ball bearing fans emerge as a preferred choice for effective cooling solutions across various electronic applications.

Introduction

The demand for advanced cooling solutions in the electronics sector is surging, driven by the need for efficiency and reliability. Ball bearing fans have emerged as a pivotal technology, offering engineers a multitude of benefits that extend beyond mere temperature regulation. Amidst the array of options available, what distinguishes ball bearing fans as the superior choice for electronics engineers? This article delves into ten key advantages of these innovative fans, revealing how they enhance performance, reduce costs, and ensure longevity in a rapidly evolving industry.

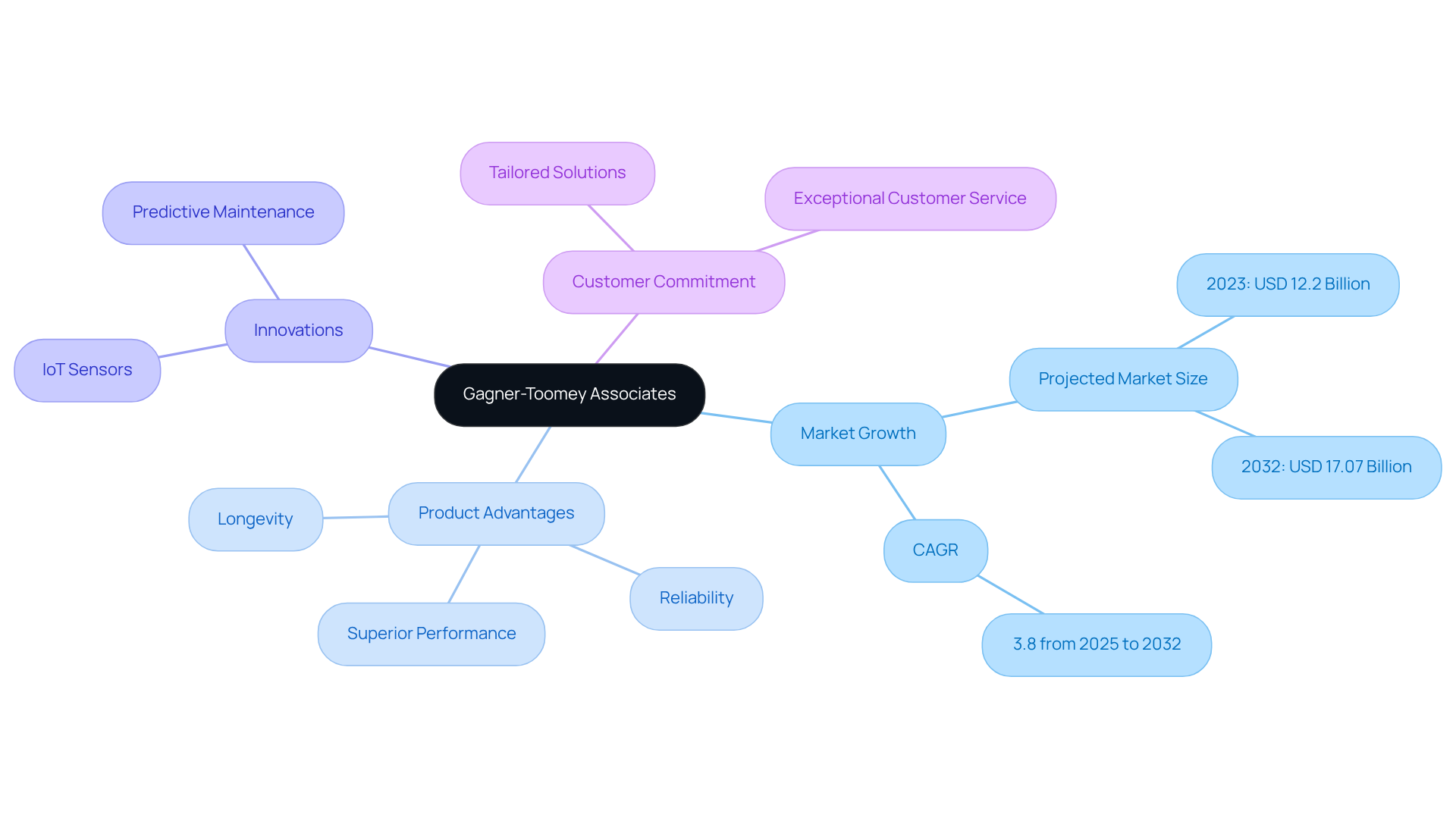

Gagner-Toomey Associates: Leading Provider of Ball Bearing Fan Solutions

Gagner-Toomey Associates distinguishes itself as a leading supplier of fan solutions, leveraging a diverse range of manufacturers to deliver cutting-edge temperature regulation technologies. The projected growth of the global ball component market, anticipated to rise from USD 12.2 billion in 2023 to USD 17.07 billion by 2032, underscores the pressing demand for effective cooling solutions. Ball bearing fans offer significant advantages for electronics engineers, providing superior performance, reliability, and longevity compared to traditional designs. These devices minimize friction and enhance airflow, which is crucial for in electronic equipment.

Recent innovations in temperature regulation technologies, including intelligent ventilators equipped with IoT sensors for real-time monitoring, are revolutionizing the industry. These advancements not only enhance efficiency but also enable predictive maintenance, thereby reducing unexpected downtimes. Gagner-Toomey Associates has effectively integrated ball support devices across various projects, showcasing their commitment to delivering tailored solutions that meet the specific temperature regulation needs of the electronics sector. Their emphasis on exceptional customer service and innovative problem-solving reinforces their position as a trusted partner for engineers in search of the most effective products for their cooling requirements.

Extended Lifespan: The Durability of Ball Bearing Fans

Ball bearing fans are known for their impressive longevity, typically achieving lifespans of 60,000 to 75,000 hours under standard operating conditions. This of the ball bearing fan arises from its innovative design, which effectively minimizes friction and wear. The versatility of ball components allows them to support both axial and radial loads, making them suitable for a wide array of applications. In high-performance environments, they require less lubrication than sleeve supports, thereby enhancing operational efficiency. Such characteristics render them particularly suitable for applications where a ball bearing fan’s reliability is paramount.

In the realm of electronics, the selection of spherical supporters can significantly impact system performance. For instance, in environments characterized by elevated temperatures and high dust concentrations, these devices maintain efficiency and extend operational lifespan. Although sphere-shaped elements may generate more noise compared to fluid dynamic supports (FDBs), their overall performance and longevity frequently outweigh this drawback. Real-world examples demonstrate that well-designed ball bearing fans not only outperform their sleeve-type counterparts but also bolster the overall reliability of electronic systems. This positions them as a preferred choice for engineers prioritizing durability and performance.

High Efficiency: Energy Savings with Ball Bearing Fans

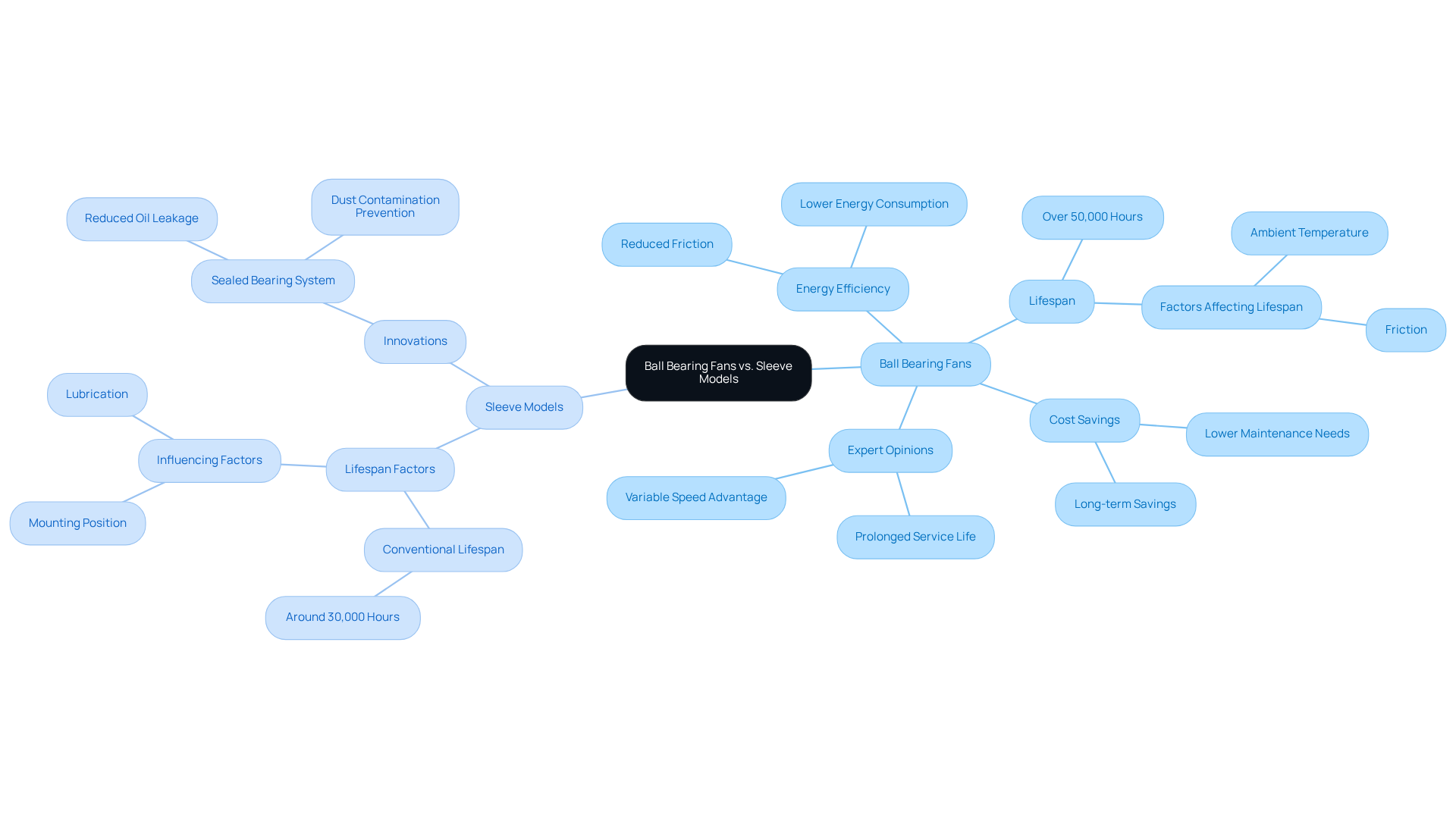

Ball spin devices operate with reduced friction, leading to lower energy consumption compared to other ventilator types. This efficiency translates into significant cost savings over time, rendering them an appealing choice for engineers aiming to improve the energy performance of their systems. Devices equipped with ball technology typically boast a lifespan exceeding 50,000 hours, while traditional sleeve models generally last around 30,000 hours. However, under certain conditions, both types can exhibit comparable lifespans, a crucial consideration for engineers.

Moreover, the energy efficiency of roller supporters can lead to decreased operational costs. By minimizing energy usage, these devices contribute to lower electricity bills, particularly in large-scale applications where multiple units are in operation. Real-world examples indicate that companies utilizing energy-efficient cooling devices have reported substantial reductions in their overall energy expenses.

Expert opinions further validate the benefits of ball bearing fans. Sam Pelonis states, ‘In these devices, the ball bearing fan offers the advantage of variable speed, prolonged service life, and improved energy efficiency.’ This highlights that the initial investment in these devices is often offset by and lower maintenance needs. Furthermore, innovations such as the ‘Sealed Bearing System’ have enhanced the performance of sleeve supports, yet ball supporters maintain a competitive edge in terms of efficiency and durability.

Factors like ambient temperature and friction can significantly affect the lifespan of sleeve support devices, making it imperative for engineers to consider these elements when selecting devices for their applications. In conclusion, the combination of reduced friction, extended service life, and decreased energy consumption positions these devices as an excellent choice for engineers seeking to improve the energy efficiency of their systems while achieving cost reductions.

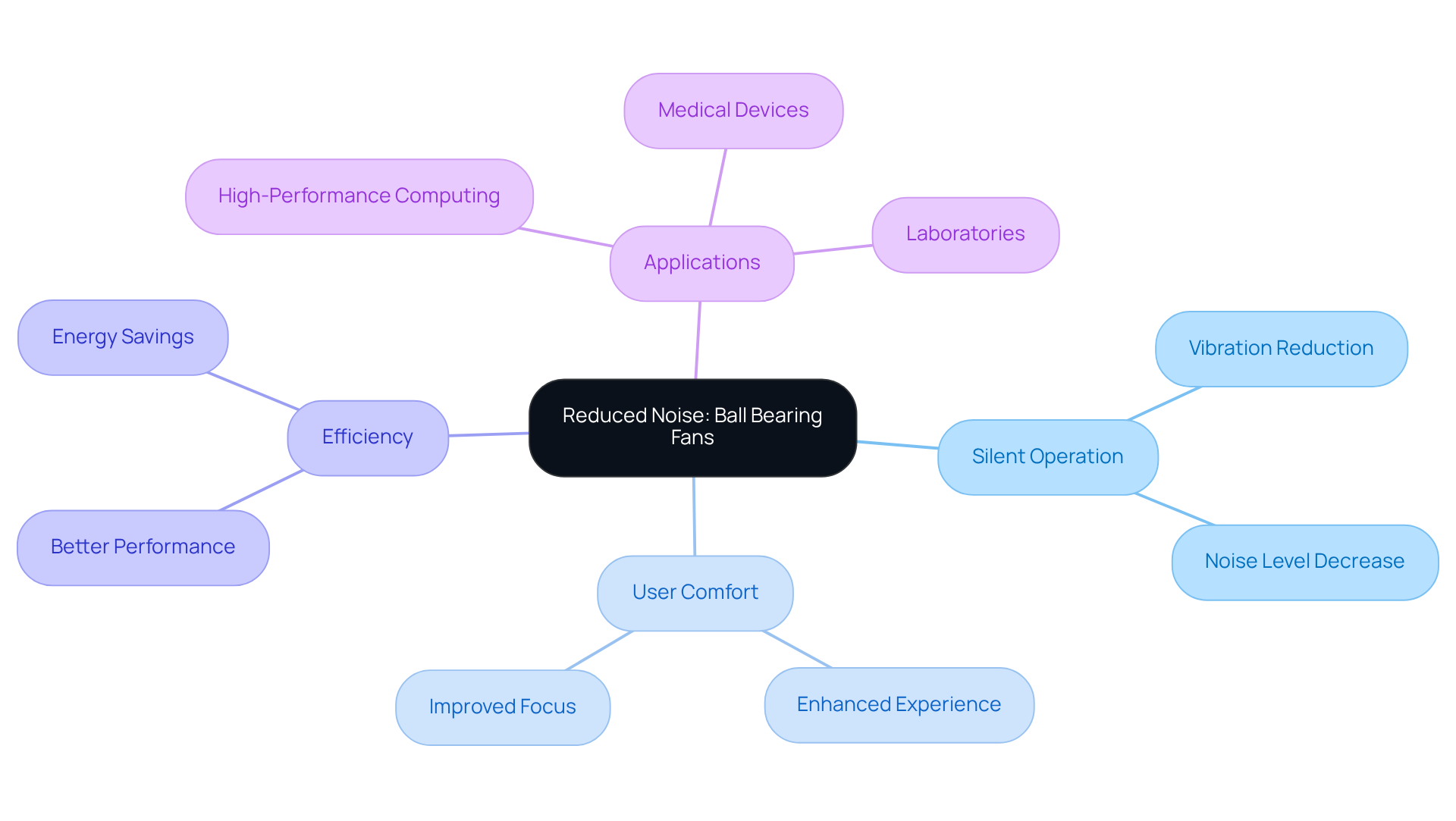

Reduced Noise: Quiet Operation of Ball Bearing Fans

Ball roller systems are engineered for silent operation, making them ideal for environments where sound minimization is critical. Their design effectively reduces vibrations, leading to significantly lower noise levels. This quiet performance not only enhances user comfort but also boosts the overall efficiency of electronic devices. Research indicates that employing roller supports can substantially diminish noise levels, representing a significant improvement for sensitive settings such as laboratories and workplaces.

Engineers have long recognized the importance of noise reduction in temperature control solutions. As one expert articulated, ‘A quieter fan not only enhances the user experience but also facilitates more precise measurements in sensitive electronic applications.’ This perspective resonates across various applications, from high-performance computing systems to medical devices, where maintaining a low noise profile is essential.

Moreover, the integration of noise reduction technologies in rotary units, including the use of a ball bearing fan, has advanced product design, empowering manufacturers to create quieter, more efficient cooling solutions. A case study on LED projection systems exemplified this, revealing that the utilization of ball bearing fans significantly curtailed operational noise while enhancing airflow, underscoring their effectiveness in real-world applications. Ultimately, the represents a crucial advantage for engineers striving to improve both efficiency and user satisfaction in their designs.

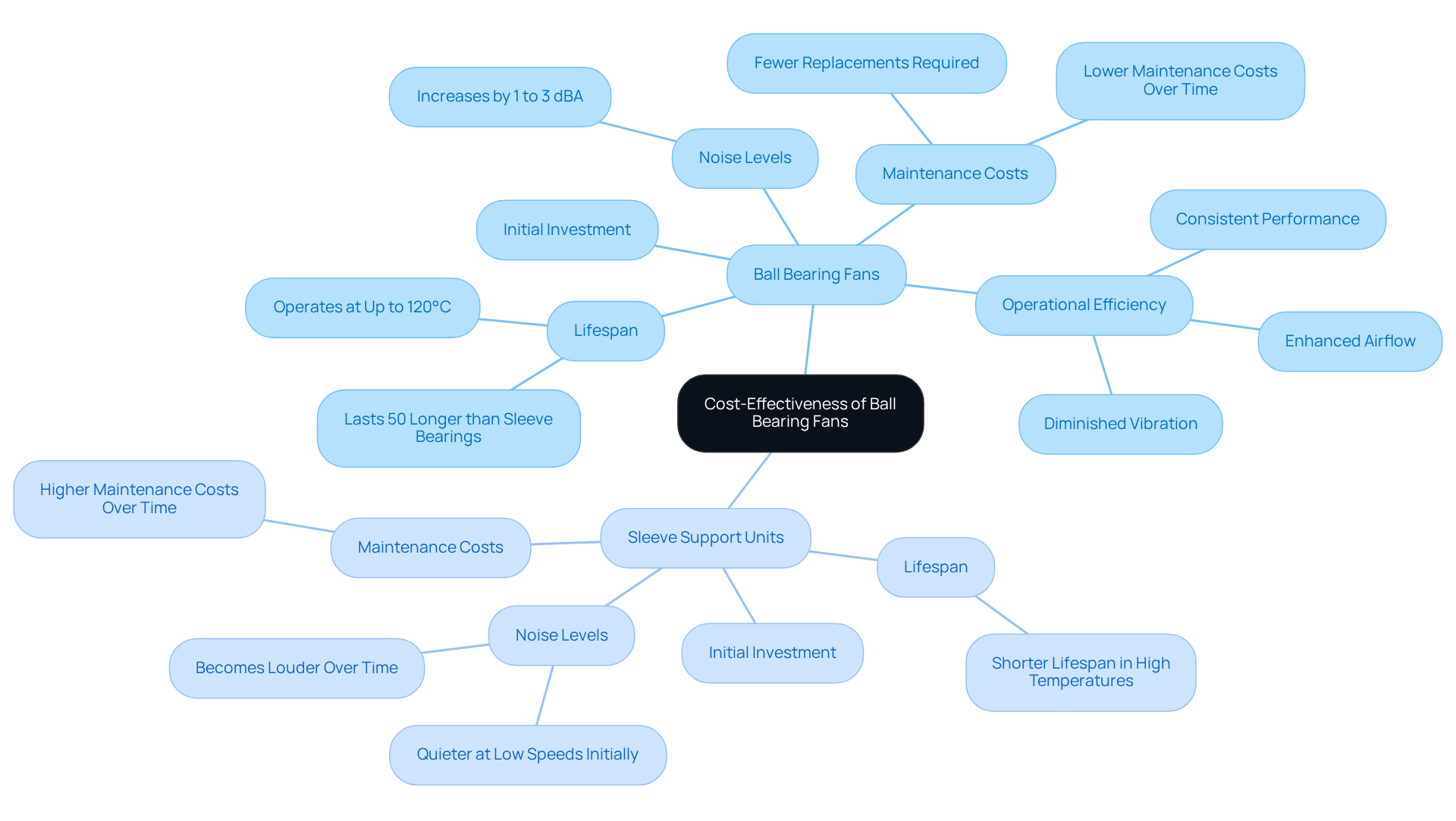

Cost-Effectiveness: Long-Term Savings with Ball Bearing Fans

Although spherical support units typically require a higher initial investment compared to sleeve support units, their extended lifespan and operational efficiency significantly lower the total cost of ownership. Ball guide units can last approximately 50% longer than their sleeve counterparts, particularly in high-temperature environments, where they can operate at temperatures up to 120°C. This durability results in fewer replacements and .

For instance, while sleeve supports may incur escalating maintenance expenses over time, spherical supports deliver consistent performance with diminished vibration, enhancing airflow and reliability. Indeed, when factoring in the reduced frequency of replacements and maintenance, the overall cost of ownership for rotating components becomes more favorable, positioning them as a financially prudent choice for engineers focused on long-term efficiency and dependability.

However, it is crucial to recognize that ball-supported devices can increase noise levels by 1 to 3 dBA compared to sleeve types, a consideration engineers should factor into their applications.

As Linkwell states, ‘Fluid dynamic supports provide outstanding durability and can manage high speeds,’ underscoring the necessity of investing in high-performance components for demanding environments.

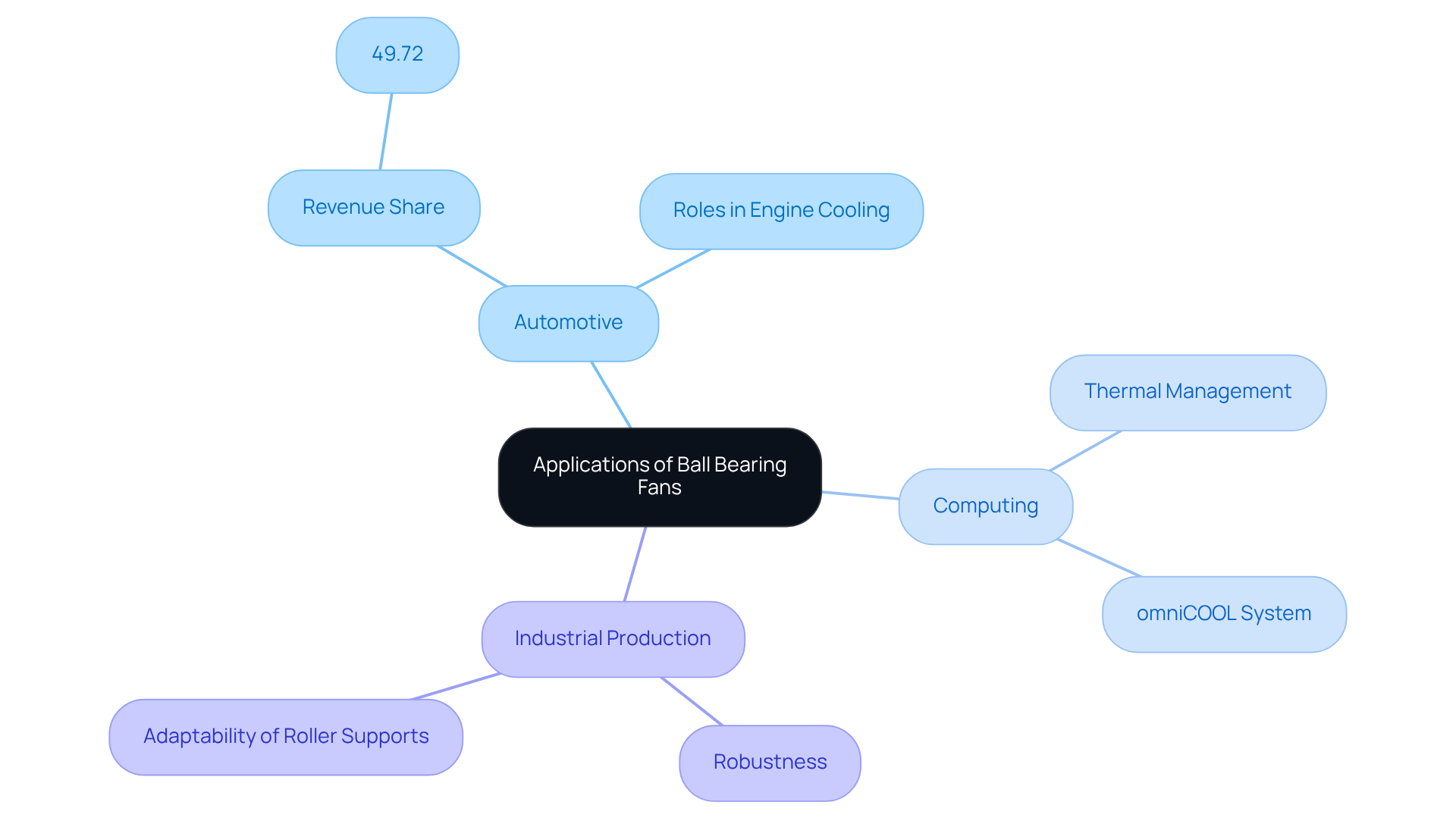

Versatility: Applications of Ball Bearing Fans in Various Industries

Ball support devices play a crucial role in diverse sectors such as computing, automotive, and industrial production, owing to their remarkable efficiency in high-temperature and challenging environments. Their design allows them to operate effectively in conditions that would challenge other fan types, making them ideal for applications that require consistent and reliable .

In the automotive sector, which represented approximately 49.72% of the revenue share in the support market in 2022, spherical support devices are vital for maintaining optimal engine temperatures, ensuring that vehicles operate efficiently and safely. Their capacity to endure high rotational speeds—up to 40% greater than conventional bearings—boosts their effectiveness in automotive cooling systems. For instance, many modern vehicles utilize spherical supports to manage temperature in engines and electronic components, contributing to improved performance and longevity.

In computing, where thermal management is paramount, roller support systems are favored for their reliability and efficiency. They are frequently employed in high-density server environments and data centers, where performance takes precedence over noise levels. The omniCOOL system, which can replace either sleeve or spherical supports without sacrificing performance, illustrates how these devices can reduce friction and noise while extending operational life, making them ideal for sensitive electronic applications.

Moreover, industries such as industrial production leverage roller supports for their robustness and ability to function across various positions and temperatures. This adaptability ensures that equipment remains operational and efficient, even in adverse conditions. As the demand for automation and advanced temperature regulation solutions grows, the role of spherical support devices in these fields is expected to expand, further solidifying their importance in modern engineering applications.

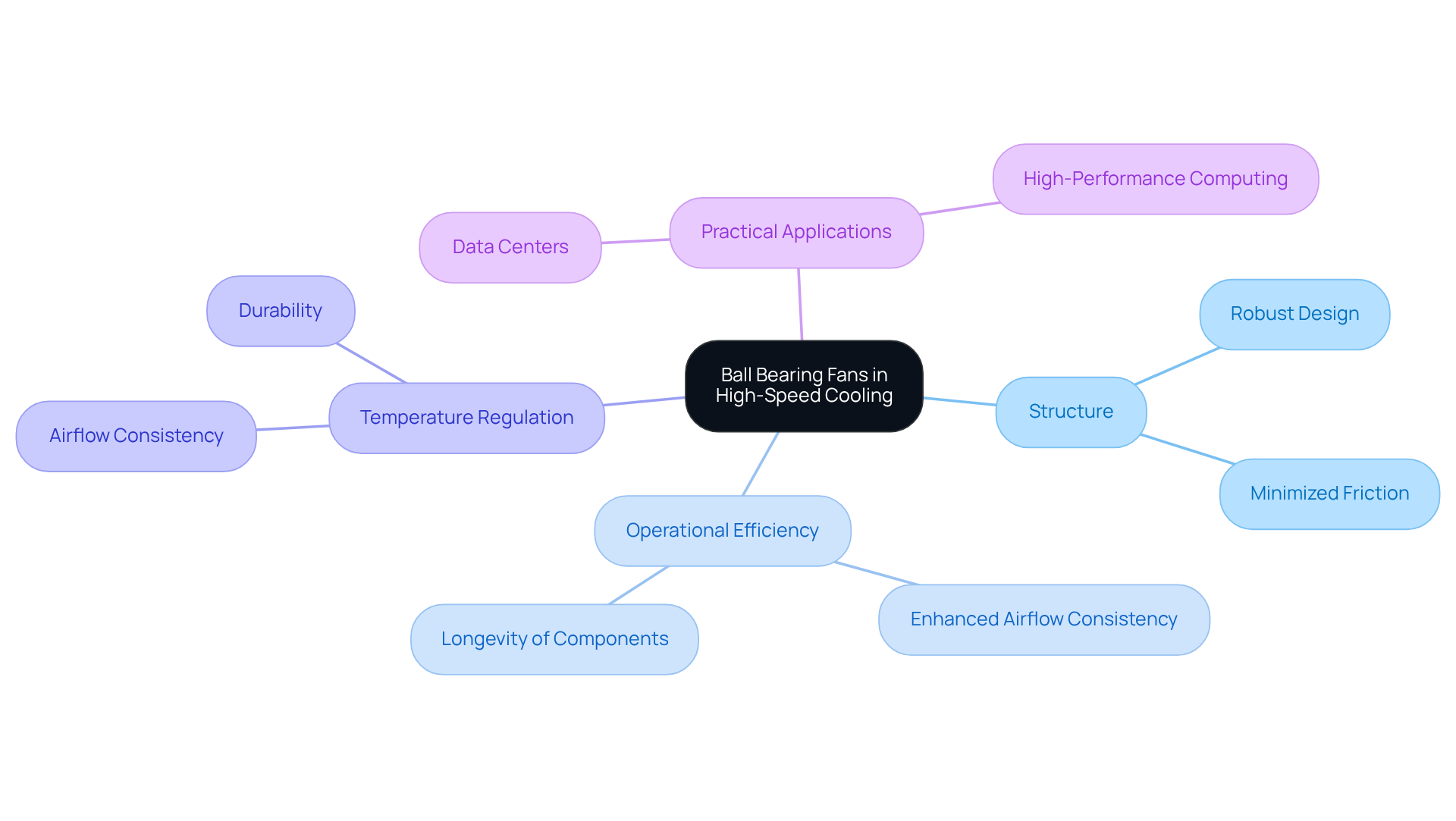

Superior Performance: Ball Bearing Fans in High-Speed Cooling

Ball support units are engineered for high-speed temperature regulation applications, showcasing a robust structure that minimizes friction and enhances operational efficiency. Their capacity to sustain consistent airflow, particularly with the use of a , is vital for effective temperature management in systems that produce significant heat, such as servers and high-performance computing devices. Notably, data indicates that these support devices can operate efficiently at temperatures up to 120°C, ensuring reliable performance even under demanding conditions.

In the context of server temperature regulation, ball bearing fans not only enhance airflow consistency but also contribute to the longevity of electronic components by mitigating the risk of overheating. Experts emphasize that the durability and efficacy of rotary devices make them indispensable in environments where maintaining optimal temperatures is critical. Practical implementations, such as those seen in data centers, demonstrate that ball bearing fans significantly improve cooling efficiency, thereby bolstering overall system reliability and performance.

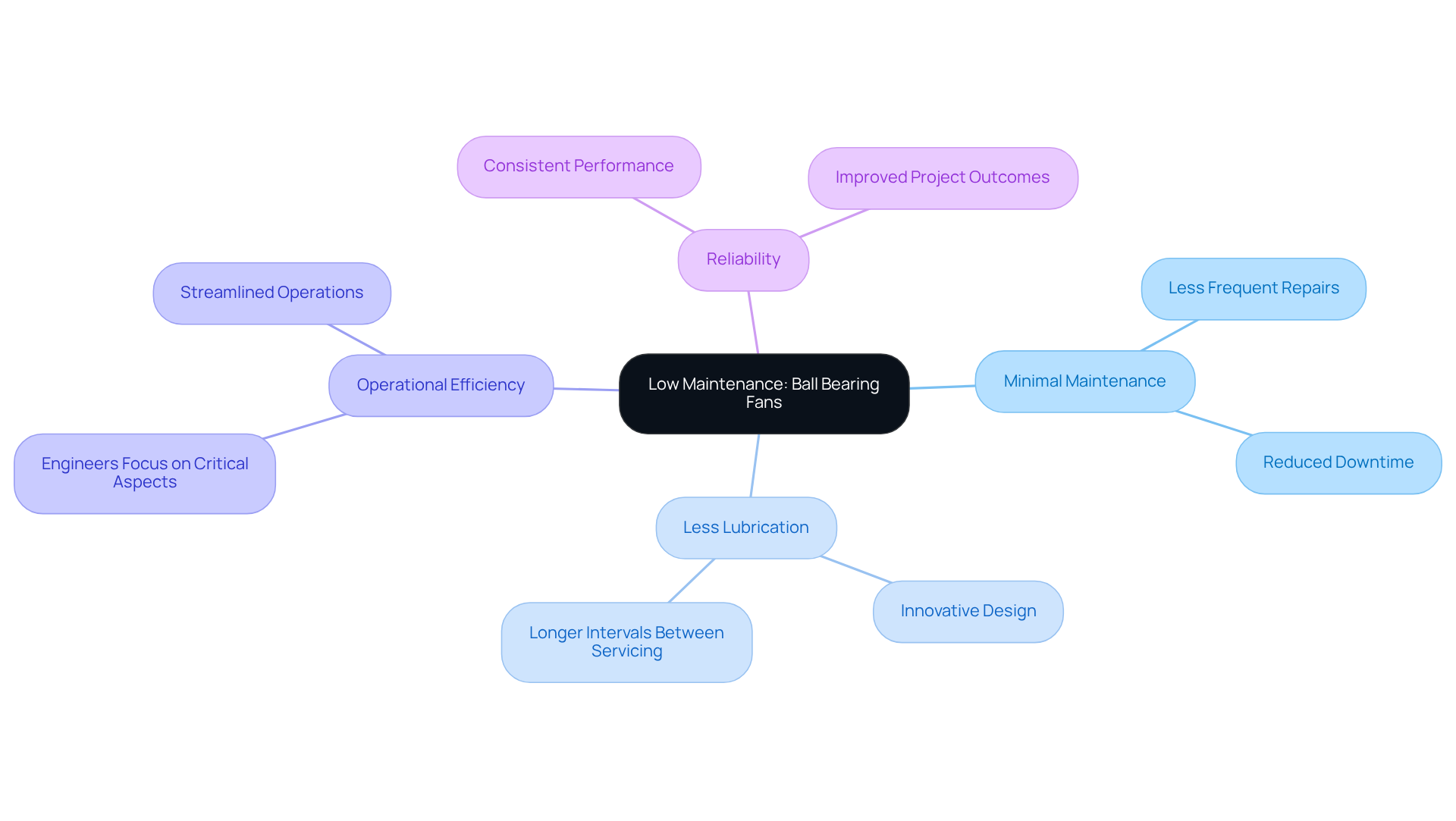

Low Maintenance: Easy Upkeep of Ball Bearing Fans

Ball bearing fans require minimal maintenance compared to other fan types, significantly enhancing their appeal. Their innovative design minimizes the necessity for regular lubrication and servicing. This efficiency allows engineers to concentrate on other critical aspects of their projects, alleviating concerns over or repairs. By integrating ball bearing fans into their systems, professionals can streamline operations and ensure reliability, ultimately leading to improved project outcomes.

Innovative Technology: Advancements in Ball Bearing Fan Design

Recent advancements in the technology of ball bearing fans have significantly improved performance and efficiency through the use of innovative materials and designs. Notably, ball bearing fan systems with dual support have emerged, providing enhanced load distribution and reduced friction, which translates to longer operational lifespans—often exceeding 50,000 hours.

Furthermore, advanced lubrication techniques, such as those found in the omniCOOL system, facilitate better lubricant circulation, minimizing wear and enhancing reliability in demanding environments. The omniCOOL system is especially remarkable for its capacity to function at any angle without the limitations of conventional sleeve supports, making it a flexible option for diverse applications.

These innovations not only tackle common problems linked to conventional sleeve supporters, such as noise and maintenance requirements, but also , increasing their popularity in the electronics sector. Statistics indicate a growing trend towards the adoption of these advanced fan designs, with recent reports showing a 20% increase in their use among electronics engineers over the past year.

Practical applications demonstrate that engineers are increasingly opting for ball bearing fans as sphere support devices due to their exceptional performance in high-speed and high-temperature situations, underscoring the significance of these developments in contemporary cooling solutions.

As Ryan Smoot, an Applications Engineer, observes, ‘Ball bearing fan designs are aimed at addressing certain disadvantages present in sleeve-type systems, providing a more dependable and effective solution for electronic systems.’

Moreover, although sleeve supports are more affordable, the long-term cost efficiency of ball bearing fans—considering their durability and lower maintenance requirements—renders them a wise investment for numerous applications.

Comprehensive Benefits: Why Ball Bearing Fans Are the Optimal Choice

Ball roller devices present a compelling array of benefits, establishing themselves as the preferred choice for engineers in the electronics sector. With a , these devices significantly outlast traditional sleeve supports, which typically operate for around 30,000 hours. This extended durability not only reduces replacement costs but also minimizes downtime in critical applications, reinforcing the argument for opting for spherical type coolers over sleeve type alternatives.

Energy efficiency stands out as another crucial advantage. Roller supporters are designed to minimize friction, resulting in lower power consumption. Their adaptability enables them to manage varying loads and speeds, making them ideal for a wide range of electronic applications, from cooling high-performance processors to optimizing airflow in compact devices.

Furthermore, ball bearing cooling devices operate at reduced noise levels, enhancing the overall user experience in environments where sound is a significant concern. Their low maintenance needs further enhance their attractiveness, as engineers can depend on these fans to deliver consistent performance without the necessity for frequent servicing.

Current market trends reveal an increasing preference for advanced temperature regulation solutions, with innovations such as electrocaloric refrigeration and natural refrigerants gaining momentum. Industry leaders emphasize the importance of selecting optimal temperature control solutions that not only meet performance criteria but also align with sustainability goals. The ongoing transition towards green refrigeration technologies is transforming the landscape, prompting engineers to consider the environmental implications of their decisions.

Practical examples underscore the effectiveness of roller-style ventilators across various applications. Facilities utilizing these devices have reported enhanced operational efficiency and significant cost savings, solidifying their reputation as a reliable temperature regulation solution. As the electronics industry continues to advance, the demand for efficient, durable, and environmentally friendly cooling solutions is set to rise, further solidifying the importance of ball bearing fans as a cornerstone of modern engineering practices.

Conclusion

Ball bearing fans have emerged as a vital component for electronics engineers, presenting a multitude of advantages that enhance performance, efficiency, and longevity across various applications. Their superior design minimizes friction, leading to lower energy consumption and extended lifespans that significantly surpass those of traditional sleeve bearing fans. This positions them as the optimal choice for engineers seeking reliable cooling solutions capable of withstanding demanding conditions and contributing to overall system reliability.

The article highlights key benefits of ball bearing fans, including:

- Impressive durability

- Energy efficiency

- Reduced noise levels

- Low maintenance requirements

With lifespans reaching up to 75,000 hours, these fans not only decrease the frequency of replacements but also lower operational costs through improved energy performance. Their versatility across different industries—from automotive to computing—underscores their critical role in modern engineering practices, particularly in high-speed cooling applications.

As the demand for effective and sustainable cooling solutions continues to grow, the significance of ball bearing fans will only increase. Engineers are encouraged to consider these advanced devices not solely for their immediate benefits but also for their long-term impact on efficiency and cost-effectiveness. Embracing innovative technologies like ball bearing fans is essential for staying at the forefront of engineering excellence and meeting the evolving challenges of the electronics industry.

Frequently Asked Questions

What distinguishes Gagner-Toomey Associates in the market for fan solutions?

Gagner-Toomey Associates is recognized as a leading supplier of fan solutions by leveraging a diverse range of manufacturers to provide advanced temperature regulation technologies, addressing the growing demand for effective cooling solutions in the electronics sector.

What is the projected growth of the global ball component market?

The global ball component market is projected to grow from USD 12.2 billion in 2023 to USD 17.07 billion by 2032.

What advantages do ball bearing fans offer compared to traditional fan designs?

Ball bearing fans provide superior performance, reliability, and longevity, minimizing friction and enhancing airflow, which is crucial for maintaining optimal operating temperatures in electronic equipment.

How do recent innovations in temperature regulation technologies impact the industry?

Innovations such as intelligent ventilators equipped with IoT sensors for real-time monitoring enhance efficiency and enable predictive maintenance, reducing unexpected downtimes.

What is the typical lifespan of ball bearing fans?

Ball bearing fans typically achieve lifespans of 60,000 to 75,000 hours under standard operating conditions.

Why are ball bearing fans considered durable?

Their innovative design minimizes friction and wear, and they require less lubrication than sleeve supports, enhancing operational efficiency and reliability.

In what environments do ball bearing fans perform particularly well?

Ball bearing fans maintain efficiency and extend operational lifespan in environments with elevated temperatures and high dust concentrations.

How do ball bearing fans compare to sleeve-type fans in terms of performance?

Well-designed ball bearing fans often outperform sleeve-type counterparts in terms of reliability and lifespan, making them a preferred choice for engineers.

What energy savings can be expected from using ball bearing fans?

Ball bearing fans operate with reduced friction, leading to lower energy consumption and significant cost savings over time compared to other ventilator types.

How does the lifespan of ball bearing fans compare to traditional sleeve models?

Ball bearing fans typically have a lifespan exceeding 50,000 hours, while traditional sleeve models generally last around 30,000 hours.

What are the benefits of using energy-efficient cooling devices in large-scale applications?

Energy-efficient cooling devices contribute to lower electricity bills and significant reductions in overall energy expenses, especially when multiple units are in operation.

What factors can affect the lifespan of sleeve support devices?

Ambient temperature and friction can significantly impact the lifespan of sleeve support devices, making it essential for engineers to consider these elements during selection.