Overview

The article titled “10 Key Insights on Centrifugal Fan Impellers for Engineers” delivers essential characteristics, applications, and innovations pertinent to centrifugal fan impellers. It equips engineers with crucial information regarding design types, performance metrics, control technologies, and future trends. This emphasis on the significance of selecting the appropriate impeller for specific operational needs is vital for enhancing efficiency and reliability across diverse industries.

Introduction

Centrifugal fan impellers are integral components in a wide array of engineering applications, spanning from HVAC systems to industrial processes where effective airflow management is paramount. As the demand for innovative cooling solutions intensifies, a comprehensive understanding of these mechanical components becomes essential. Engineers face significant challenges in optimizing performance while navigating the delicate balance of efficiency, noise, and maintenance. This exploration presents ten key insights that shed light on the complexities and advancements in centrifugal fan impeller technology, equipping engineers with the critical knowledge necessary to refine their designs and applications.

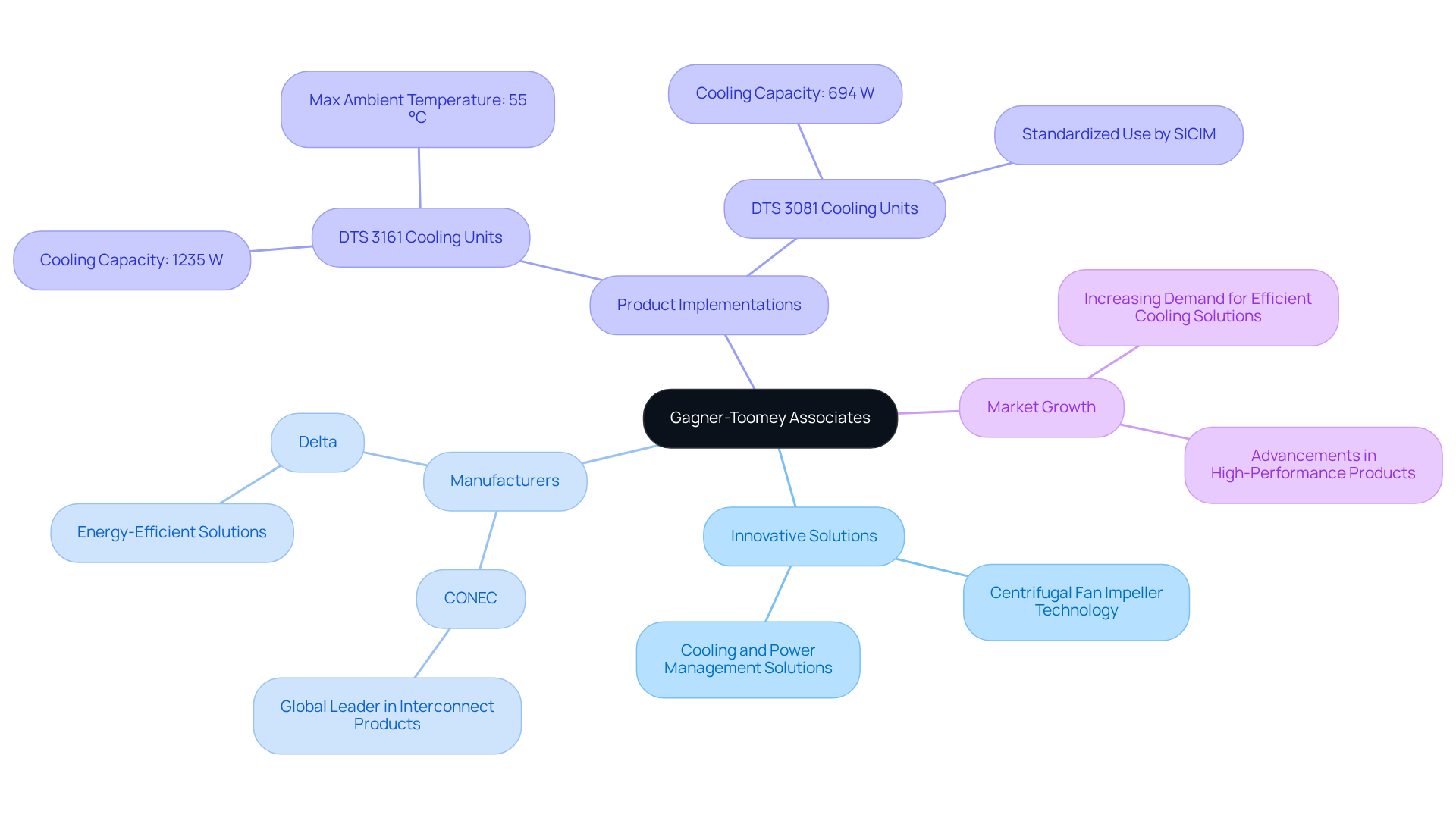

Gagner-Toomey Associates: Innovative Solutions for Centrifugal Fan Impellers

Gagner-Toomey Associates leads the way in centrifugal fan impeller technology innovation, offering engineers state-of-the-art cooling and power management solutions. By collaborating with a diverse array of manufacturers, including industry leaders like CONEC and Delta, the company ensures that clients receive tailored solutions that meet the specific demands of their applications.

With over 40 years of experience, CONEC is acknowledged as a , while Delta excels in energy-efficient solutions and power electronics. This dedication to excellence is illustrated by successful implementations, such as the deployment of Pfannenberg’s DTS 3161 cooling units, which deliver dependable thermal management with a cooling capacity of 1235 W under extreme conditions, safeguarding critical components’ operational safety.

Furthermore, SICIM has standardized the use of approximately 70 DTS 3081 cooling units over five years, showcasing their reliability and efficiency in challenging environments. With a maximum ambient temperature rating of 55 °C for outdoor applications, Gagner-Toomey remains committed to advancing the development of high-performance products that address the evolving requirements of the electronics industry.

As the market for centrifugal fan impellers continues to grow, driven by an increasing demand for efficient cooling solutions, Gagner-Toomey is at the forefront of this innovation.

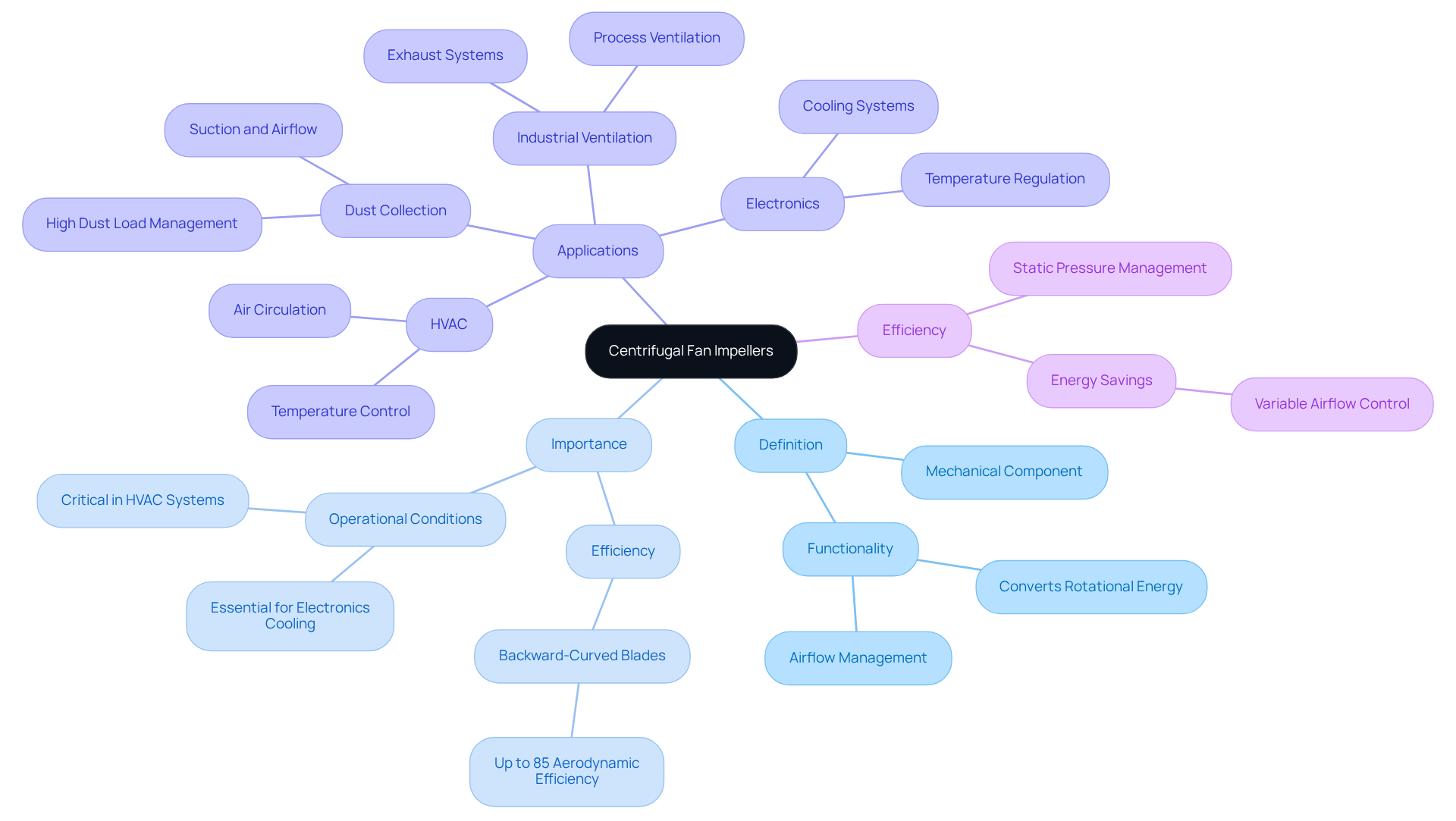

Centrifugal Fan Impellers: Definition and Importance

The centrifugal fan impeller represents a specialized mechanical component engineered to efficiently transport air or gases by converting rotational energy into kinetic energy. These blades function by drawing air into the rotor’s center and expelling it outward through the centrifugal fan impeller, a mechanism vital for effective airflow management. This process is particularly critical in , industrial ventilation, and electronic cooling applications, where maintaining optimal operating conditions is paramount.

Notably, statistics reveal that backward-curved blades can achieve up to 85% aerodynamic efficiency, positioning them as ideal solutions for high-pressure environments. Their utility extends to dust collection systems, where they generate the necessary suction and airflow to capture particles from diverse sources, thereby ensuring clean and safe operational environments.

In the realm of electronics, the centrifugal fan impeller is indispensable in cooling systems, playing a crucial role in temperature regulation and performance enhancement, thereby underscoring its significance across multiple sectors.

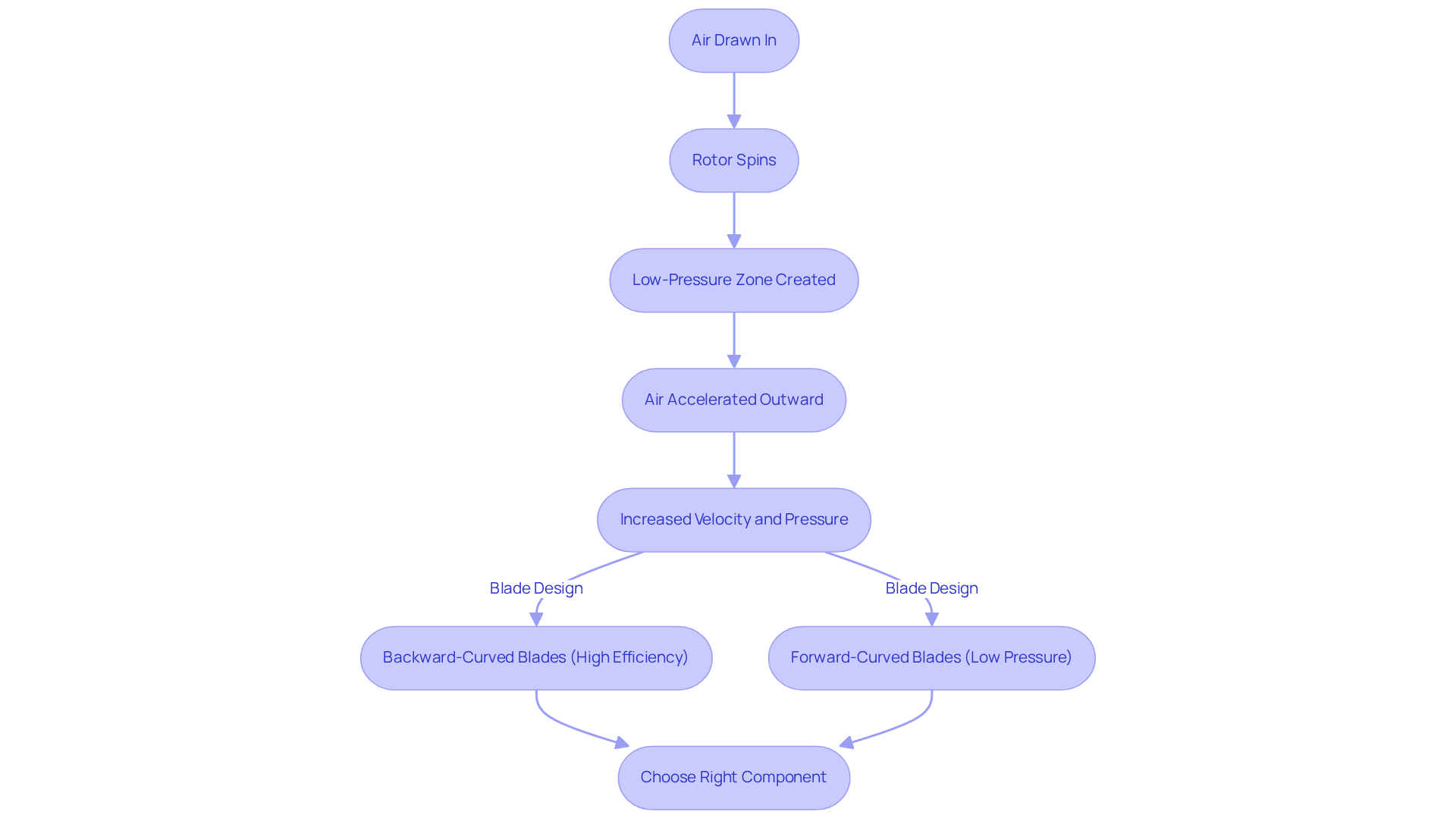

How Centrifugal Fan Impellers Work: Principles of Operation

Centrifugal fan impeller blades are engineered based on the principles of fluid dynamics. As the rotor spins, it creates a low-pressure zone at its center, effectively drawing air in. The blades subsequently accelerate the air outward, resulting in an increase in both its velocity and pressure. This phenomenon is governed by Bernoulli’s principle, which asserts that an increase in the speed of a fluid is accompanied by a decrease in pressure.

The design of the rotor blades, including their angle and curvature, significantly influences the . For instance, backward-curved blades, commonly found in centrifugal fan impellers, are renowned for their exceptional performance and ability to operate under elevated static pressures, making them ideal for demanding applications. Conversely, forward-curved blades are optimized for low-pressure HVAC systems, underscoring the vital role of blade design in enhancing airflow and energy efficiency.

A case study titled ‘Choosing the Right Fan Component for Dust-Laden Manufacturing’ illustrates that selecting the appropriate component is crucial for maintaining optimal airflow and system efficiency in high-resistance environments. Furthermore, the K Series and Ch Series components are meticulously designed to meet specific airflow and pressure requirements, further highlighting the necessity of choosing the right component for particular operational demands.

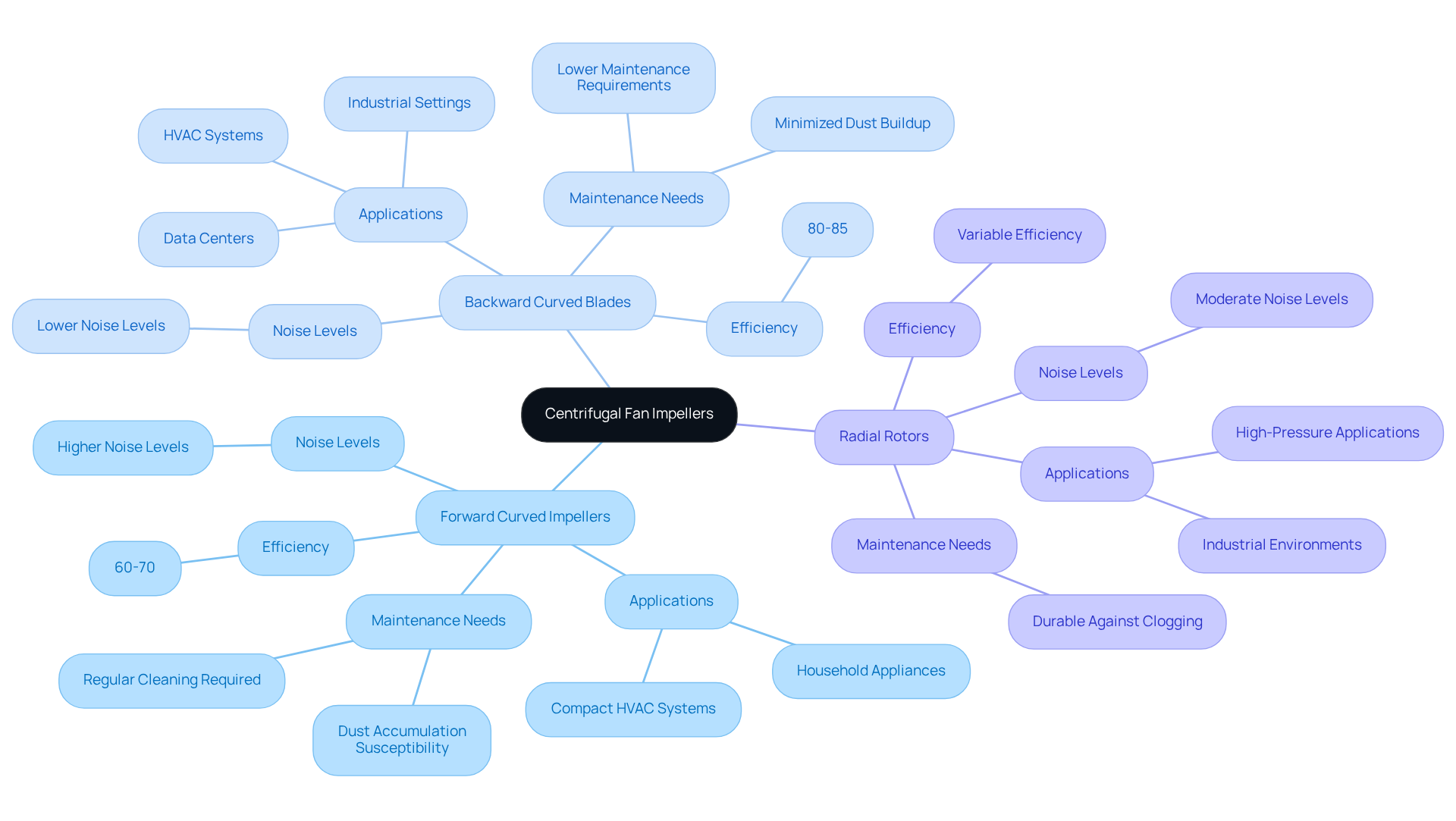

Types of Centrifugal Fan Impellers: Design and Application

Centrifugal fan impellers are meticulously designed in various configurations, each tailored for specific applications. The primary types include:

- Forward Curved Impellers: These impellers are adept at delivering high airflow at low pressure, making them particularly suitable for applications requiring the movement of large volumes of air, such as household appliances and compact HVAC systems. Their effectiveness typically ranges from 60-70%. However, their design makes them susceptible to dust accumulation, necessitating regular maintenance, which can contribute to elevated noise levels.

- Backward Curved Blades: Renowned for their performance and quieter operation, backward curved blades are especially appropriate for high-pressure applications. They operate with an , positioning them as a preferred choice in industrial settings, HVAC systems, and data centers. For example, the Z Series can achieve airflows up to 400,000 m³/h and pressures reaching 9,000 Pa. Their design effectively minimizes dust buildup, resulting in lower maintenance requirements and enhanced durability—essential for environments demanding stable airflow.

- Radial Rotors: Engineered for high-pressure and low-flow applications, radial fans are often employed in industrial environments where robust performance is crucial. These devices excel at managing particulate-laden air, offering high static pressure capabilities while ensuring durability against clogging.

The performance, efficiency, and noise levels of each rotor type are significantly influenced by the design of the centrifugal fan impeller. Therefore, it is imperative for engineers to select the appropriate rotor based on specific operational requirements and environmental conditions. Additionally, material selection plays a vital role, especially in harsh environments, where options like abrasion-resistant steel and FRP can enhance both durability and performance.

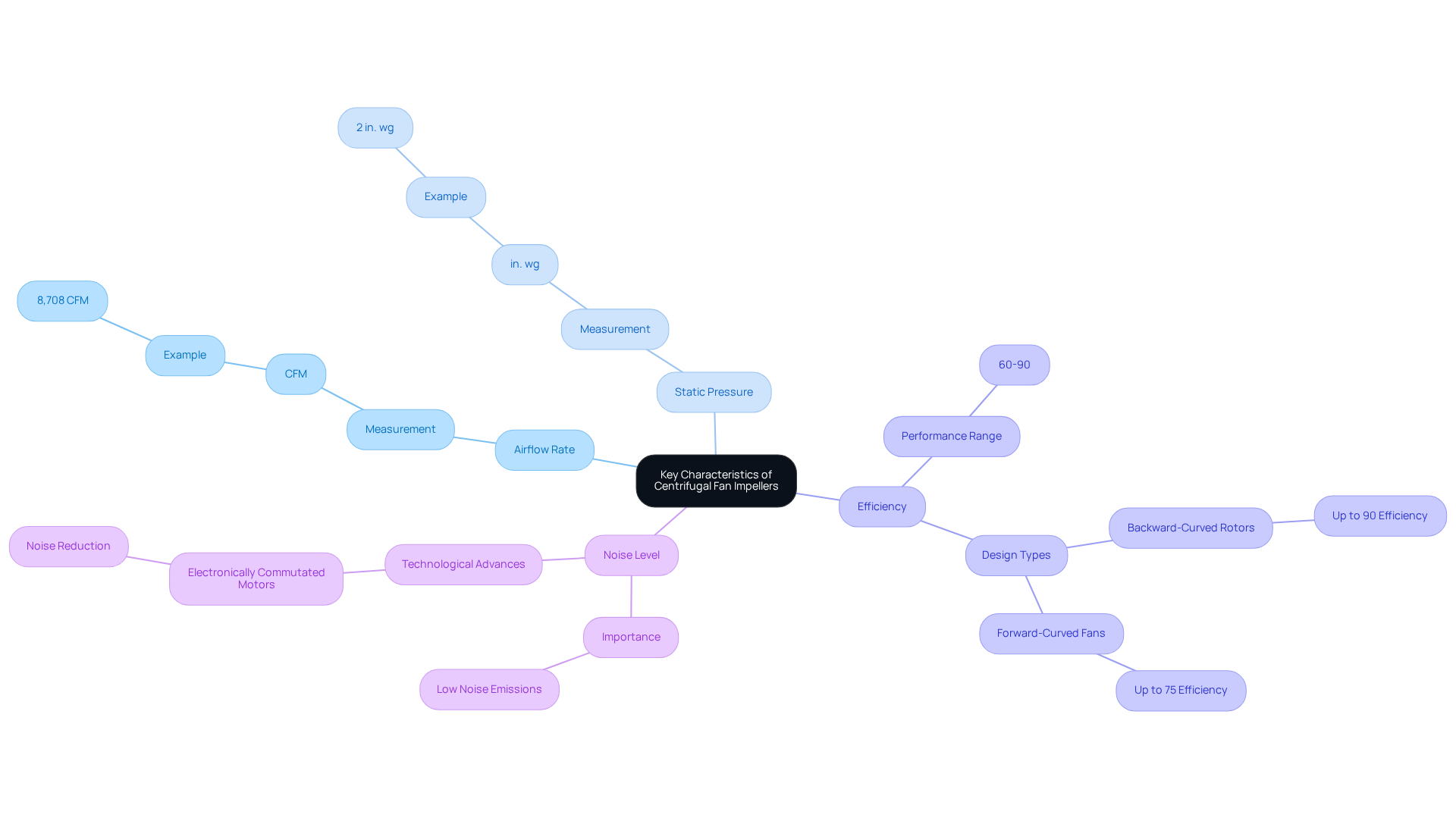

Key Characteristics of Centrifugal Fan Impellers: Performance Metrics

Understanding the performance and application of centrifugal fan impellers requires knowledge of their key characteristics.

- Airflow Rate: This metric indicates the volume of air moved by the fan, typically measured in cubic feet per minute (CFM). For instance, a fan operating at 8,708 CFM demonstrates its capability to manage substantial air movement across various applications.

- Static Pressure: This refers to the resistance the fan must overcome to move air through a system, measured in inches of water gauge (in. wg). A fan may achieve a static pressure of 2 in. wg under standard conditions, which is crucial for ensuring effective airflow in duct systems.

- Efficiency: Efficiency is defined as the ratio of useful work performed by the fan to the energy consumed, often expressed as a percentage. Centrifugal fan impellers can exhibit performance levels ranging from 60% to 90%, contingent upon design and operational conditions. For example, backward-curved rotors can reach performance levels of up to 90%, making them ideal for high-performance applications.

- Noise Level: The sound produced during operation is a critical factor, particularly in environments where low noise emissions are essential. Fans designed with advanced technologies, such as electronically commutated motors, can significantly reduce noise levels while maintaining high efficiency.

Understanding these metrics is crucial for engineers to select the appropriate rotor for specific requirements, thereby ensuring in their applications.

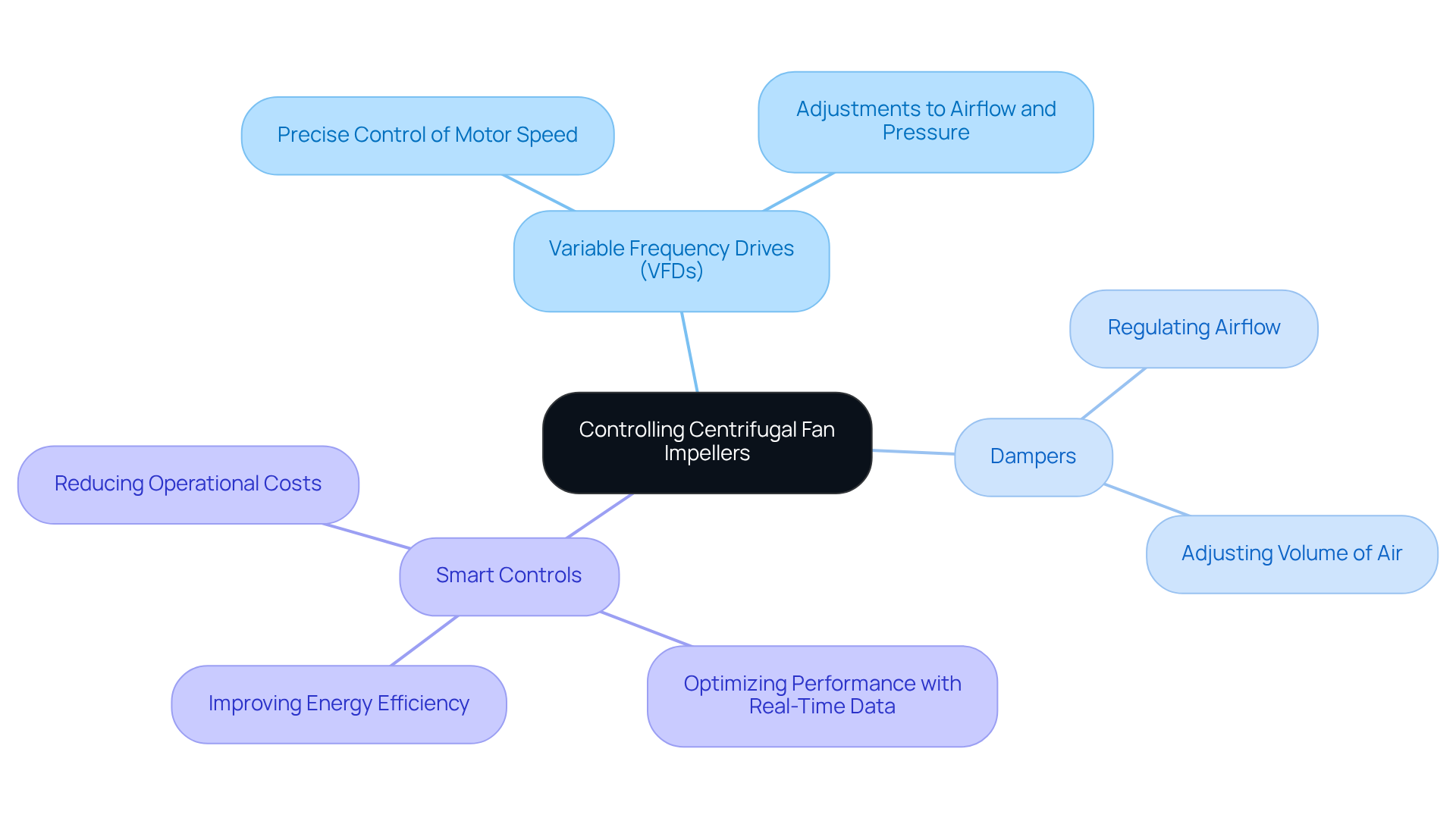

Controlling Centrifugal Fan Impellers: Techniques and Technologies

Controlling the centrifugal fan impeller requires the application of various techniques and technologies that significantly enhance system performance.

- Variable Frequency Drives (VFDs): These devices enable precise control of motor speed, allowing for necessary adjustments to airflow and pressure.

- Dampers: Essential for regulating airflow, dampers adjust the volume of air entering or exiting the system, ensuring optimal operation.

- Smart Controls: By integrating sensors and automation, smart controls optimize performance based on real-time data, which improves energy efficiency and reduces operational costs.

Implementing these control strategies not only enhances the performance of centrifugal fan impeller systems but also positions organizations to achieve .

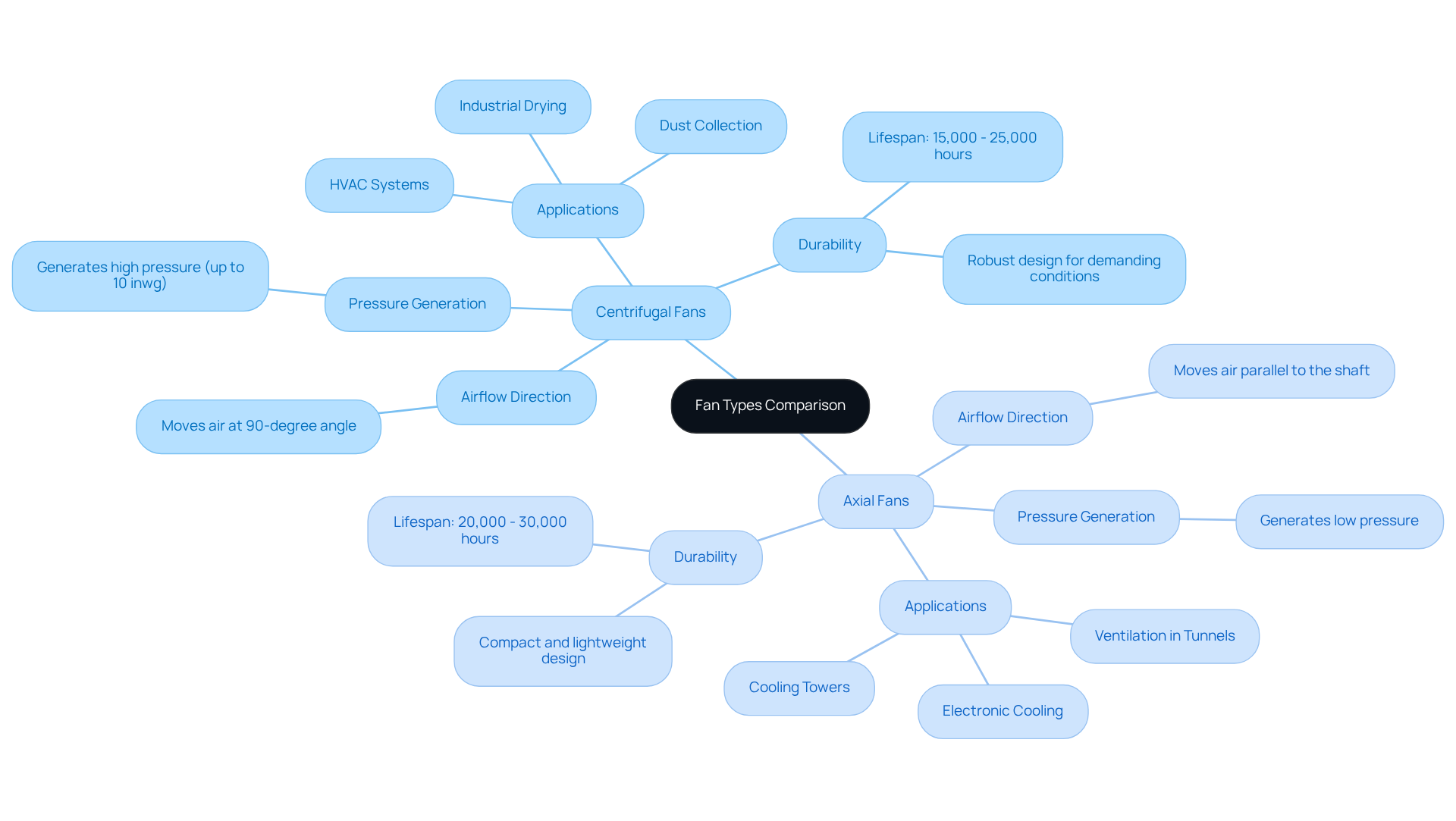

Centrifugal Fans vs. Axial Fans: A Comparative Analysis

Centrifugal fan impellers and axial fans are designed for distinct operational needs, with each having unique characteristics that are critical to their applications.

Centrifugal Fans: These fans move air perpendicular to the axis of rotation, generating high pressure while typically producing lower airflow rates. They excel in systems that require overcoming high resistance, such as dust collection, fume extraction, and industrial drying processes that utilize a centrifugal fan impeller. For instance, centrifugal blowers that feature a centrifugal fan impeller are frequently utilized in HVAC systems and industrial boilers to sustain oxygen levels for combustion, ensuring effective functioning in high-pressure settings. Capable of generating pressures up to 10 inches of water gauge (inwg), the sturdy construction of the centrifugal fan impeller enables it to manage fine and lightweight substances, making it appropriate for uses involving dust, moisture, or particulate matter.

Axial Devices: In contrast, axial devices move air parallel to the axis, delivering high airflow rates at lower pressures. They are ideal for applications such as cooling and ventilation, particularly in confined spaces where efficiency is crucial. Axial blowers are commonly employed in cooling towers, electronic cooling systems, and large-scale air circulation, where they can achieve airflow rates of up to 5,000 cubic feet per minute with minimal resistance. Typically more energy efficient than other types, their compact design makes them a cost-effective option for general ventilation needs.

Understanding these distinctions is essential for engineers when selecting the appropriate centrifugal fan impeller for specific applications, thereby ensuring . Furthermore, while centrifugal fans generally entail higher upfront costs, they offer long-term durability, an important consideration for budget-conscious engineers.

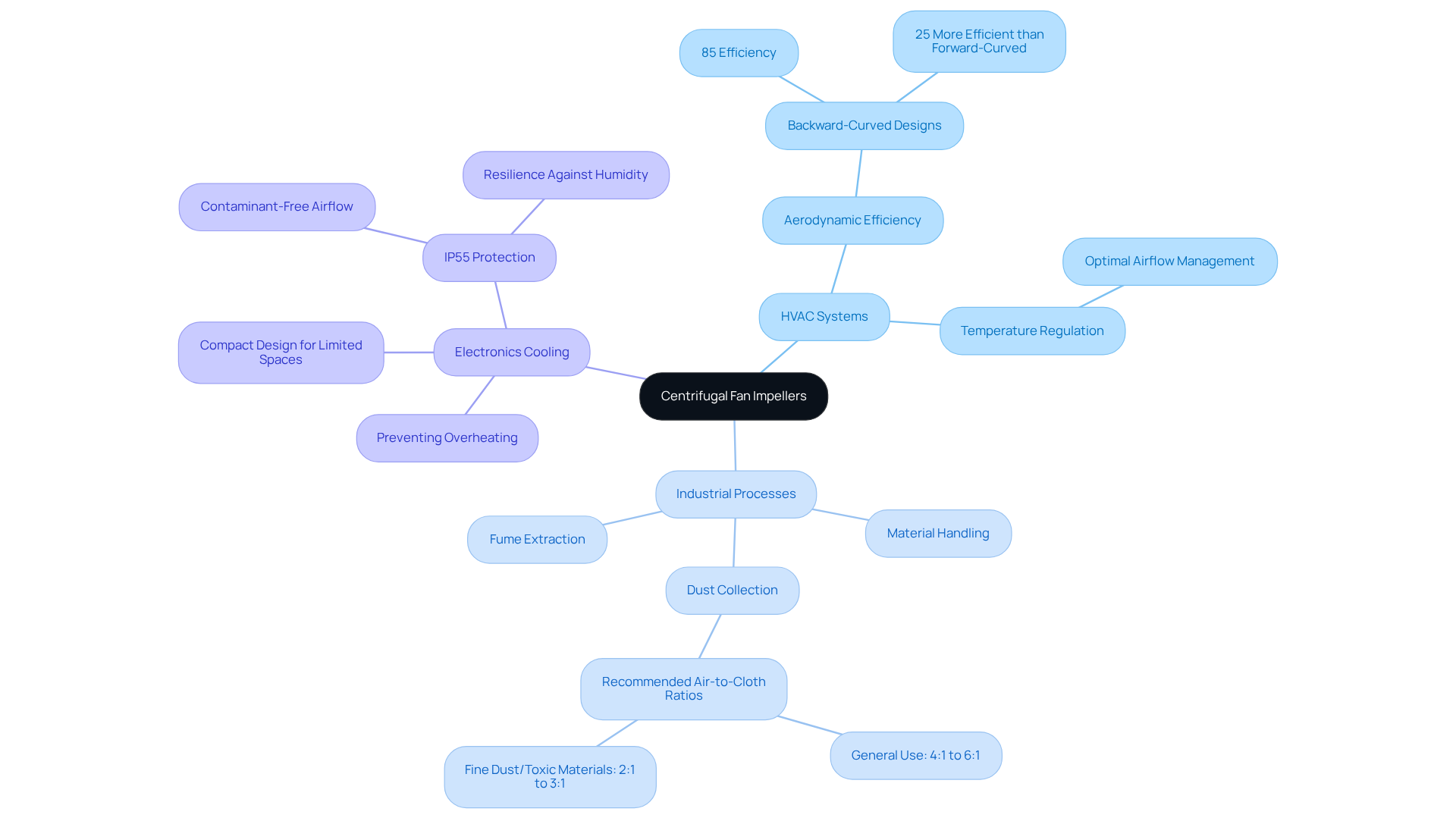

Applications of Centrifugal Fan Impellers: Industries and Uses

Centrifugal fan impellers are essential in various industries, showcasing impressive versatility and efficiency.

- HVAC Systems: The centrifugal fan impeller serves as a critical component of heating, ventilation, and air conditioning systems, ensuring optimal airflow and temperature regulation. For example, backward-curved designs achieve up to 85% aerodynamic efficiency, surpassing forward-curved models by 25%, making them particularly suitable for continuous operation in these applications.

- Industrial Processes: Within manufacturing and processing facilities, centrifugal blowers are vital for material handling, dust collection, and fume extraction. Their capacity to sustain high static pressure enables effective management of , such as dust and vapors, thereby fostering a safer and cleaner working environment. Recommended air-to-cloth ratios for efficient dust collection typically range from 4:1 to 6:1 for general industrial use, and 2:1 to 3:1 for fine dust or toxic materials.

- Electronics Cooling: Centrifugal blowers are essential for maintaining optimal temperatures in electronic devices and systems, preventing overheating and ensuring reliability. Small centrifugal blowers, specifically designed for compact areas, deliver efficient airflow in sensitive applications, such as laboratory equipment and IT environments, where precise cooling is crucial. As industry experts have noted, ‘IP55 centrifugal units deliver consistent, contaminant-free airflow even during frequent washdowns or disinfection,’ underscoring their significance in preserving operational integrity in these environments.

The adaptability of the centrifugal fan impeller across these sectors emphasizes its crucial role in enhancing operational effectiveness and reliability.

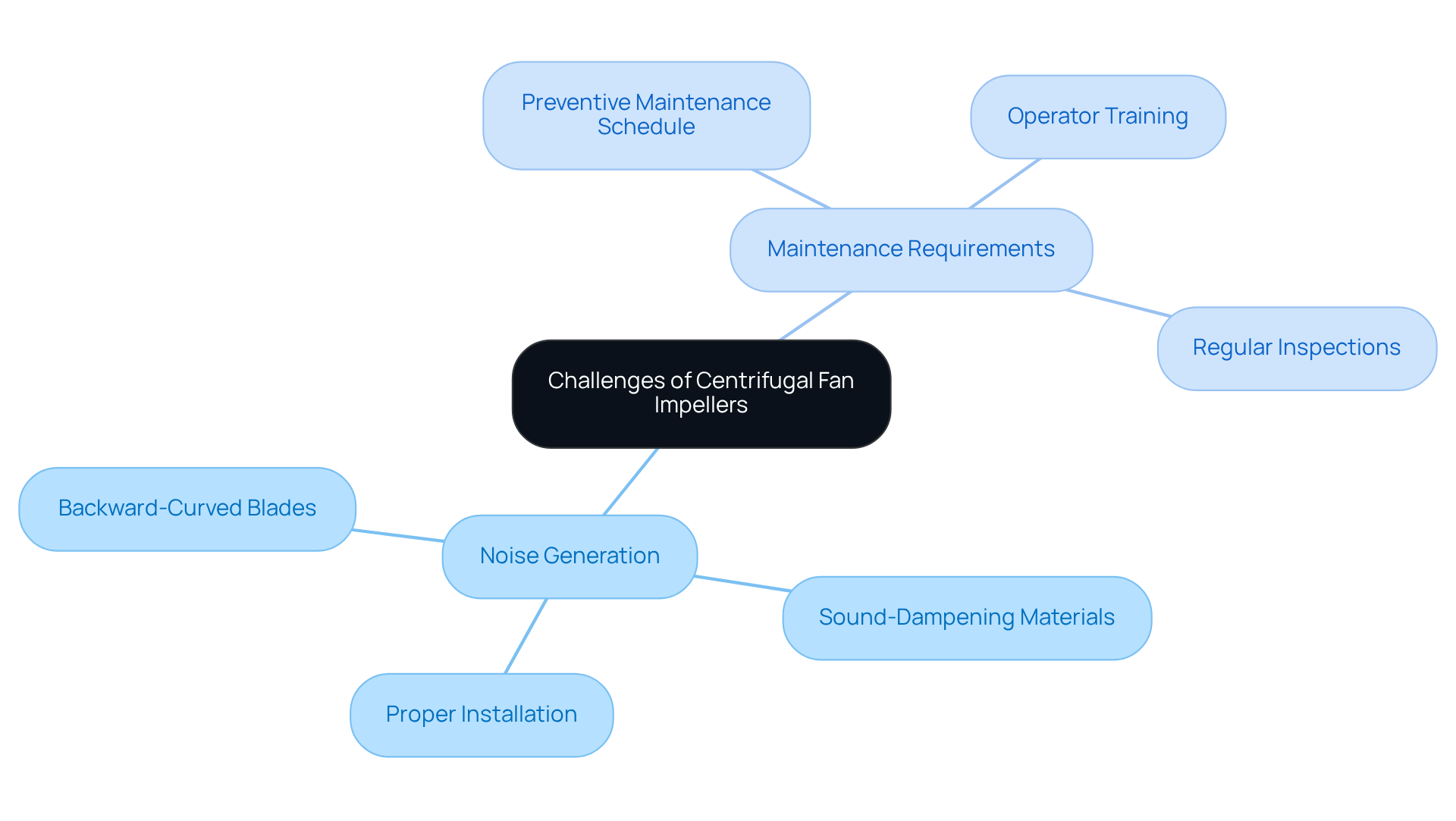

Challenges of Centrifugal Fan Impellers: Noise and Maintenance Issues

Centrifugal fan impellers encounter several significant challenges, mainly related to noise generation and maintenance requirements.

- Noise Generation: The high-speed operation of centrifugal fans can produce considerable noise, posing challenges in sensitive environments. To mitigate this issue, engineers can implement solutions such as backward-curved blades, specifically designed to . Furthermore, incorporating sound-dampening materials into the fan housing can significantly minimize acoustic emissions, resulting in a quieter operational environment. Proper installation and alignment of the fan are also crucial, as these factors greatly influence noise levels and overall performance.

- Maintenance Requirements: Regular maintenance is essential to prevent common issues such as dirt accumulation, imbalance, and component wear. Establishing a preventive maintenance schedule is vital for ensuring optimal performance and longevity of the fan system. This schedule should include regular inspections, cleaning, and lubrication, adhering to manufacturer guidelines to guarantee optimal performance. Statistics indicate that a well-maintained centrifugal fan impeller can have a service life ranging from 10 to 20 years; however, this lifespan can vary based on maintenance practices and operating conditions. Operators should also be trained to recognize potential problems early and perform basic maintenance tasks, facilitating timely interventions that can prevent costly repairs and downtime.

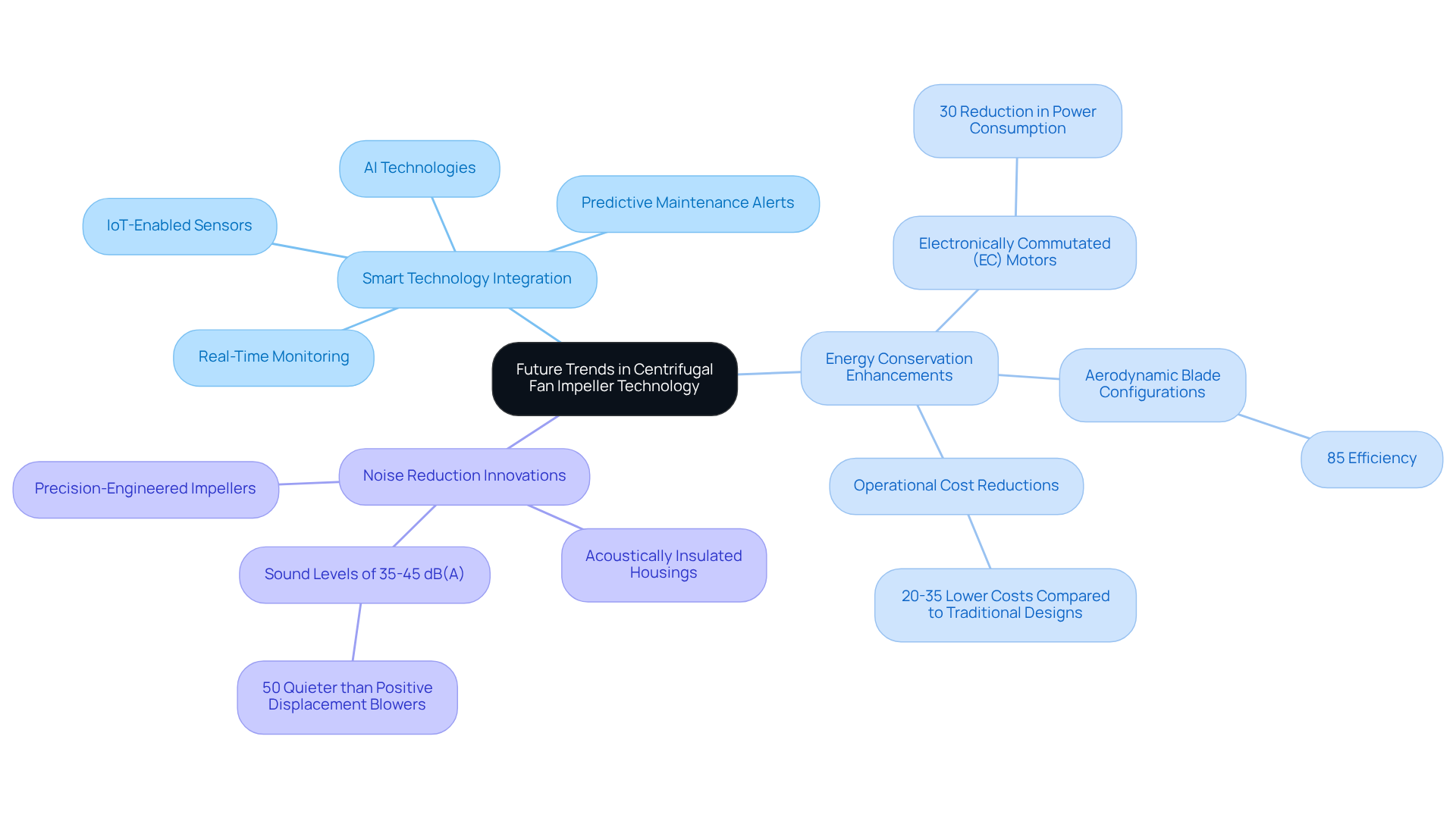

Future Trends in Centrifugal Fan Impeller Technology: Innovations Ahead

The future of centrifugal fan impeller technology is poised for transformative advancements, characterized by several key trends:

- Smart Technology Integration: The incorporation of IoT-enabled sensors and AI technologies is revolutionizing fan systems, enabling real-time monitoring and optimization of performance. This advanced technology facilitates , informing users in advance about potential downtime, thereby enhancing operational performance.

- Energy Conservation Enhancements: Current research focuses on innovative materials and designs that significantly elevate energy performance. For instance, contemporary centrifugal blowers equipped with electronically commutated (EC) motors can reduce power consumption by up to 30%. Additionally, the innovative aerodynamic blade configurations and backward-curved components of the centrifugal fan impeller achieve an impressive 85% efficiency, which contributes to operational cost reductions of 20-35% compared to traditional designs.

- Noise Reduction Innovations: As noise pollution increasingly concerns industrial and commercial environments, the development of quieter fan designs has become essential. Innovations such as precision-engineered centrifugal fan impellers and acoustically insulated housings have resulted in centrifugal fans operating at sound levels of 35-45 dB(A), rendering them 50% quieter than positive displacement blowers.

These trends not only shape the future landscape of centrifugal fan technology but also drive enhancements in performance, sustainability, and user comfort across various applications.

Conclusion

Centrifugal fan impellers are integral to a wide range of engineering applications, including HVAC systems and industrial processes, as they efficiently manage airflow and enhance operational performance. Their design and functionality are essential for ensuring effective cooling and ventilation, underscoring their significance in maintaining optimal conditions across various sectors.

Key insights indicate that the selection of impeller design—whether backward-curved or forward-curved—has a profound effect on efficiency, noise levels, and maintenance requirements. A thorough understanding of operational principles, such as fluid dynamics and static pressure, empowers engineers to choose the most appropriate impeller type for their specific applications. Furthermore, the emergence of smart technology and energy-efficient designs is revolutionizing the future of centrifugal fan impellers, paving the way for enhanced performance and sustainability.

As industries progress, adopting innovations in centrifugal fan technology will be crucial for achieving greater efficiency and reliability. Engineers are urged to remain abreast of emerging trends and to account for the unique demands of their applications when selecting fan systems. Investing in the right centrifugal fan impeller technology not only optimizes performance but also fosters long-term operational success and environmental sustainability.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for its innovative solutions in centrifugal fan impeller technology, providing engineers with advanced cooling and power management solutions.

Who are some of the manufacturers that Gagner-Toomey Associates collaborates with?

Gagner-Toomey collaborates with various manufacturers, including industry leaders like CONEC and Delta, to deliver tailored solutions that meet specific application demands.

What is the significance of CONEC and Delta in the context of Gagner-Toomey Associates?

CONEC is a global leader in interconnect products with over 40 years of experience, while Delta specializes in energy-efficient solutions and power electronics, both contributing to Gagner-Toomey’s commitment to excellence in product development.

Can you provide an example of a successful implementation by Gagner-Toomey Associates?

An example is the deployment of Pfannenberg’s DTS 3161 cooling units, which provide reliable thermal management with a cooling capacity of 1235 W, ensuring operational safety under extreme conditions.

How many DTS 3081 cooling units has SICIM standardized over the years?

SICIM has standardized the use of approximately 70 DTS 3081 cooling units over five years, demonstrating their reliability and efficiency in challenging environments.

What is the maximum ambient temperature rating for Gagner-Toomey’s cooling units?

The maximum ambient temperature rating for their cooling units is 55 °C for outdoor applications.

What is a centrifugal fan impeller and why is it important?

A centrifugal fan impeller is a mechanical component designed to transport air or gases efficiently by converting rotational energy into kinetic energy, playing a critical role in airflow management in HVAC systems, industrial ventilation, and electronic cooling applications.

What is the aerodynamic efficiency of backward-curved blades in centrifugal fan impellers?

Backward-curved blades can achieve up to 85% aerodynamic efficiency, making them ideal for high-pressure environments.

How do centrifugal fan impeller blades operate based on fluid dynamics?

As the rotor spins, it creates a low-pressure zone at its center, drawing air in. The blades then accelerate the air outward, increasing its velocity and pressure, in accordance with Bernoulli’s principle.

What factors influence the efficiency of centrifugal fan impellers?

The design of the rotor blades, including their angle and curvature, significantly affects the efficiency, with backward-curved blades being optimal for high static pressures, while forward-curved blades are suited for low-pressure HVAC systems.

Why is choosing the right fan component important in specific applications?

Selecting the appropriate fan component is crucial for maintaining optimal airflow and system efficiency, particularly in high-resistance environments, as highlighted in the case study ‘Choosing the Right Fan Component for Dust-Laden Manufacturing’.