Overview

The essential features of 20000 CFM fans for engineers encompass:

- Airflow efficiency

- Noise level management

- Durability

- Energy efficiency

- Safety features

- Ease of installation and maintenance

- Versatility of applications

- Control options

- Warranty and support services

These features are critical in addressing the challenges faced in various industrial settings. The article emphasizes the significance of design, material quality, and technology integration, which collectively enhance performance, sustainability, and user satisfaction across a range of applications. By focusing on these attributes, engineers can make informed decisions that optimize operational efficiency and reliability.

Introduction

In the realm of high-capacity ventilation, the demand for 20,000 CFM fans has surged, propelled by the necessity for effective cooling solutions across diverse industries. This article explores ten essential features that engineers must consider when selecting these powerful air movers, emphasizing how advancements in technology can significantly enhance performance and efficiency. However, with a multitude of options available, how can engineers ensure they choose the right fan that not only meets their specific requirements but also endures the test of time?

Gagner-Toomey Associates: Innovative Cooling Solutions for 20000 CFM Fans

Gagner-Toomey Associates specializes in delivering innovative cooling solutions tailored specifically for high-capacity systems. By collaborating with leading manufacturers, they ensure engineers have access to cutting-edge technologies that significantly improve ventilation and thermal management. This unwavering commitment to excellence is evident in their proficiency in tackling intricate cooling challenges, positioning them as a . The integration of advanced cooling technologies not only elevates performance but also plays a crucial role in enhancing energy efficiency and promoting sustainability across diverse applications.

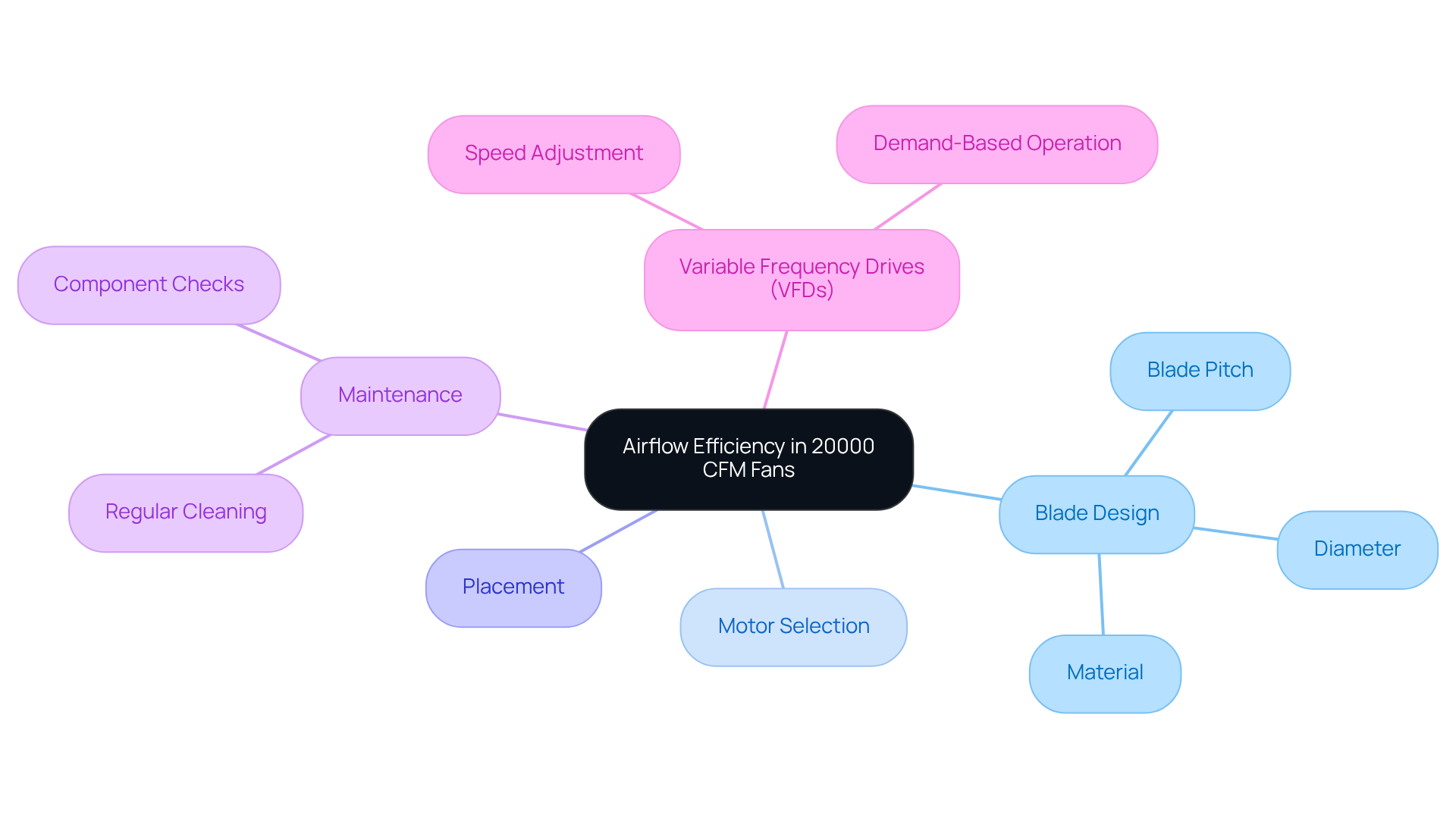

Airflow Efficiency: Maximizing Performance in 20000 CFM Fans

Maximizing air movement efficiency in a 20000 cfm fan units is a critical challenge that requires optimizing blade design, motor selection, and placement. Gagner-Toomey Associates, the globe’s largest producer of standard and custom air-movers, provides an extensive range of DC input Tube Axial fans and Centrifugal Blowers, essential for achieving superior ventilation performance. Engineers must consider several factors, including:

- Blade pitch

- Diameter

- Material

to enhance air movement while minimizing turbulence. Furthermore, implementing variable frequency drives (VFDs) allows for the adjustment of fan speed based on demand, significantly improving overall efficiency. Regular maintenance and cleaning of fan components are also vital for over time.

Noise Level: Ensuring Quiet Operation in 20000 CFM Fans

To address the challenge of silent operation in high-capacity air movers, engineers must prioritize:

Utilizing larger, significantly reduces noise levels while effectively maintaining airflow. Furthermore, the integration of sound-dampening materials and vibration isolation mounts serves to further diminish operational noise. Regular maintenance checks are essential, as they enable the identification and rectification of any issues that could lead to increased noise levels. By implementing these strategies, engineers can ensure optimal performance while minimizing disruptive sounds.

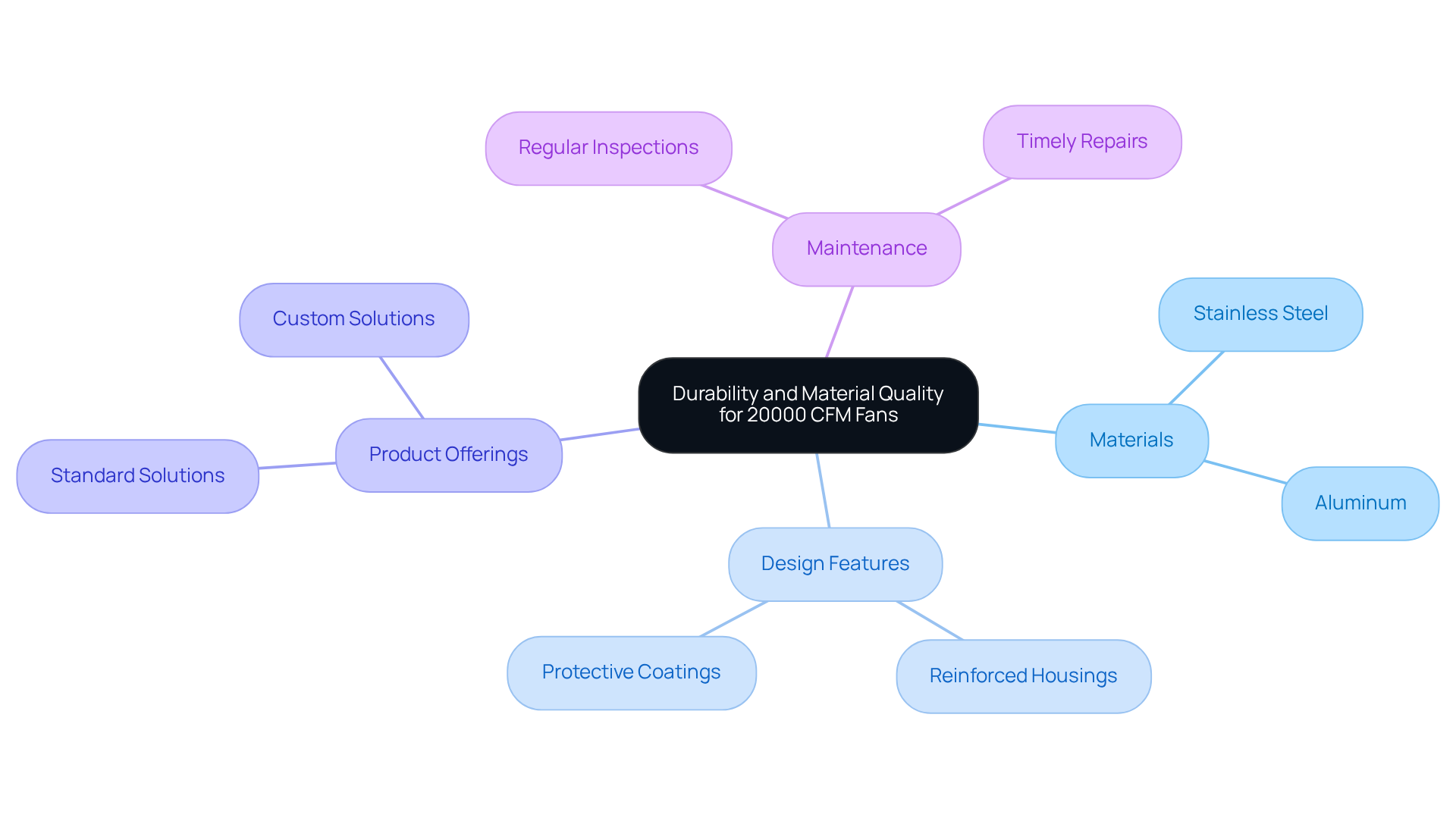

Durability and Material Quality: Key Considerations for 20000 CFM Fans

When selecting a 20000 cfm fan, the durability and material quality are of utmost importance. Gagner-Toomey Associates delivers units crafted from premium materials such as stainless steel and aluminum, which provide exceptional resistance to corrosion and wear, ensuring durability even in demanding environments.

Engineers must also evaluate the fan’s design, including features like reinforced housings and protective coatings, as these are crucial for enhancing durability. Furthermore, Gagner-Toomey’s extensive product line encompasses both standard and custom solutions, enabling tailored airflow solutions that cater to specific application requirements.

Regular inspections and maintenance are essential for identifying wear and tear, facilitating , and ultimately maximizing the efficiency and lifespan of these critical components.

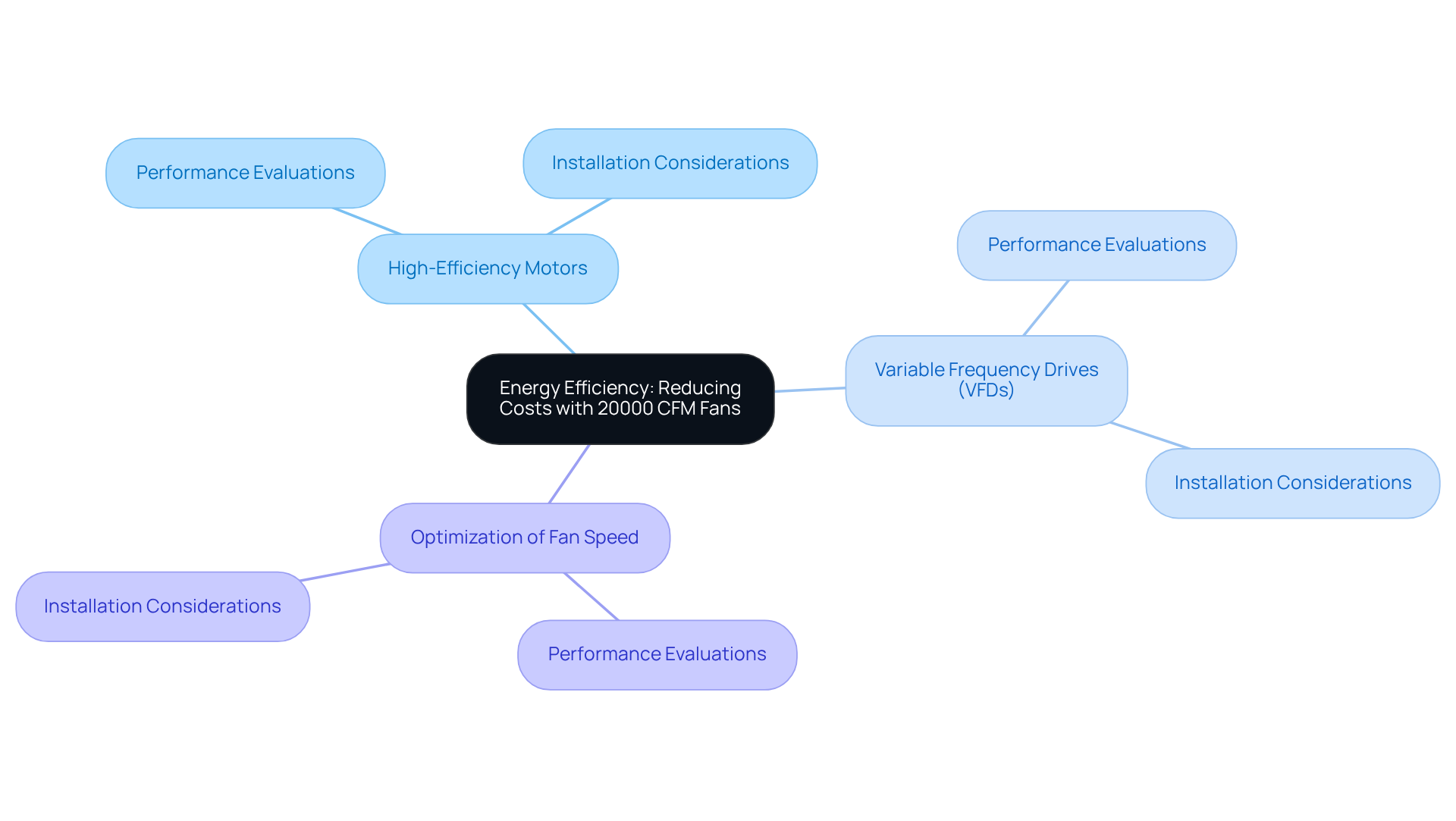

Energy Efficiency: Reducing Costs with 20000 CFM Fans

Achieving energy efficiency in high-capacity blowers is a critical challenge that can be addressed through several effective strategies.

- High-efficiency motors

- Implementation of variable frequency drives (VFDs)

- Optimization of fan speed in response to real-time demand

These are proven methods to significantly . Furthermore, engineers must consider the operational environment of the fan, ensuring proper installation to minimize potential energy losses. By conducting regular performance evaluations, organizations can identify specific areas for enhancement, ensuring that their devices operate at peak efficiency.

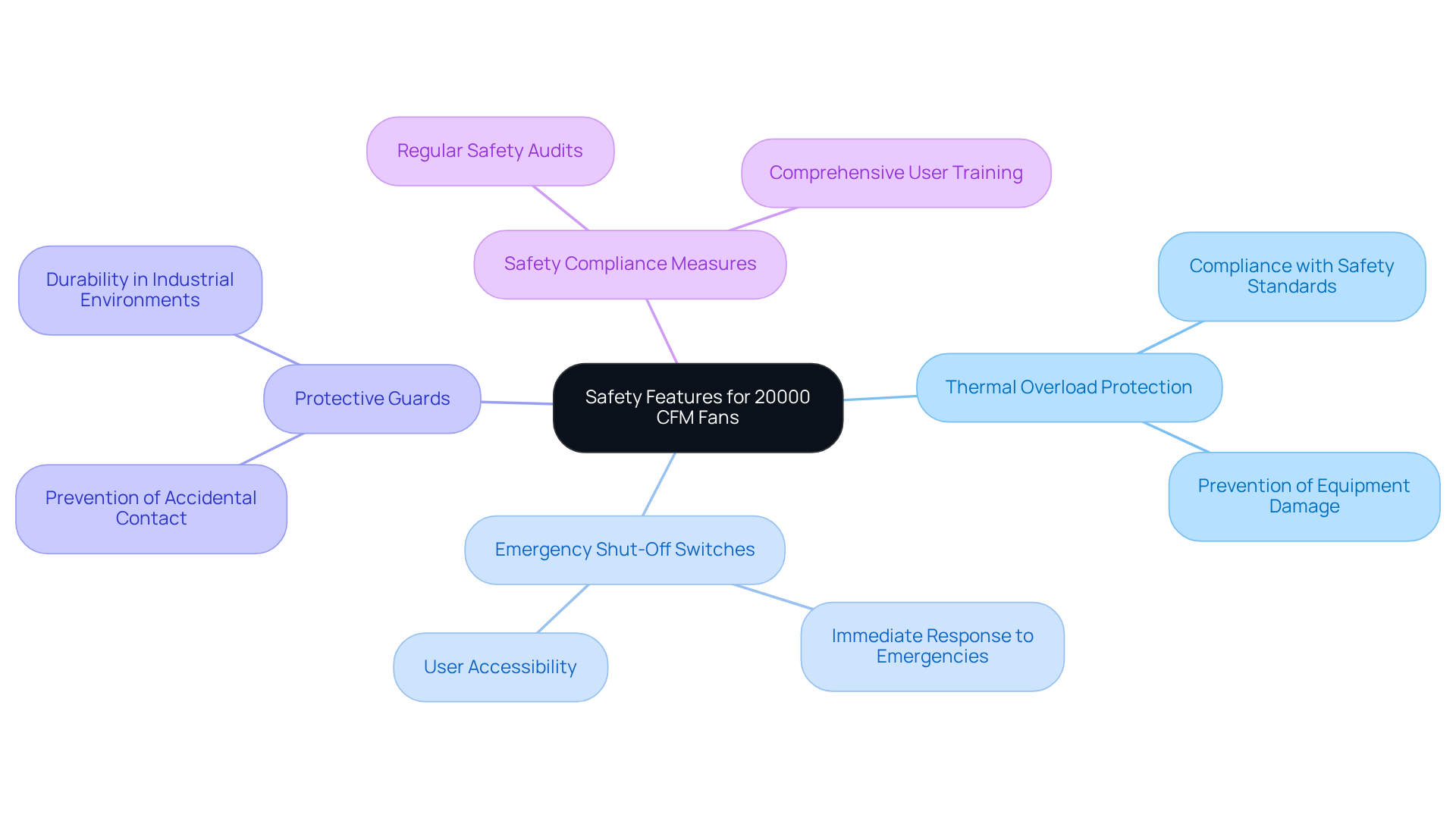

Safety Features: Protecting Users with 20000 CFM Fans

Integrating safety elements in high-capacity CFM units is not merely advisable; it is essential for user protection. Key features such as:

- Thermal overload protection

- Emergency shut-off switches

- Protective guards

are critical to preventing accidental contact with moving parts. Adherence to applicable safety standards and regulations is imperative, ensuring these measures are suitable for industrial environments. To further bolster , regular safety audits and comprehensive training for users are highly recommended.

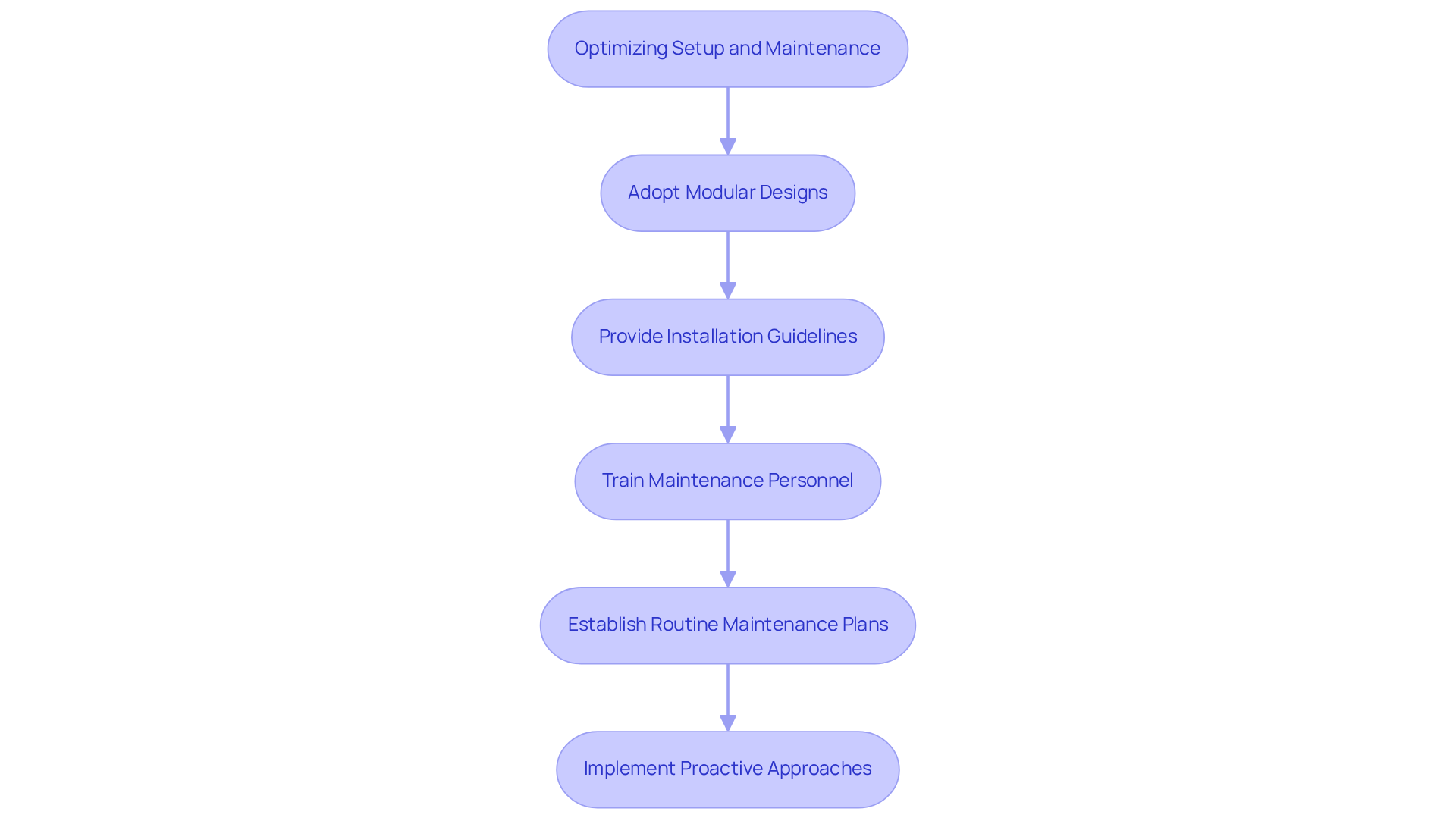

Ease of Installation and Maintenance: Streamlining 20000 CFM Fan Operations

Optimizing the setup and upkeep of large capacity air movers presents a significant challenge that requires meticulous planning and design. Engineers are encouraged to adopt modular designs that facilitate easy assembly and disassembly, thereby streamlining the installation process.

By providing clear installation guidelines and comprehensive training for maintenance personnel, organizations can significantly reduce downtime and enhance operational efficiency.

Furthermore, establishing routine maintenance plans is essential to ensure that equipment is serviced promptly, which in turn minimizes the risk of unforeseen breakdowns. This proactive approach not only but also boosts overall productivity.

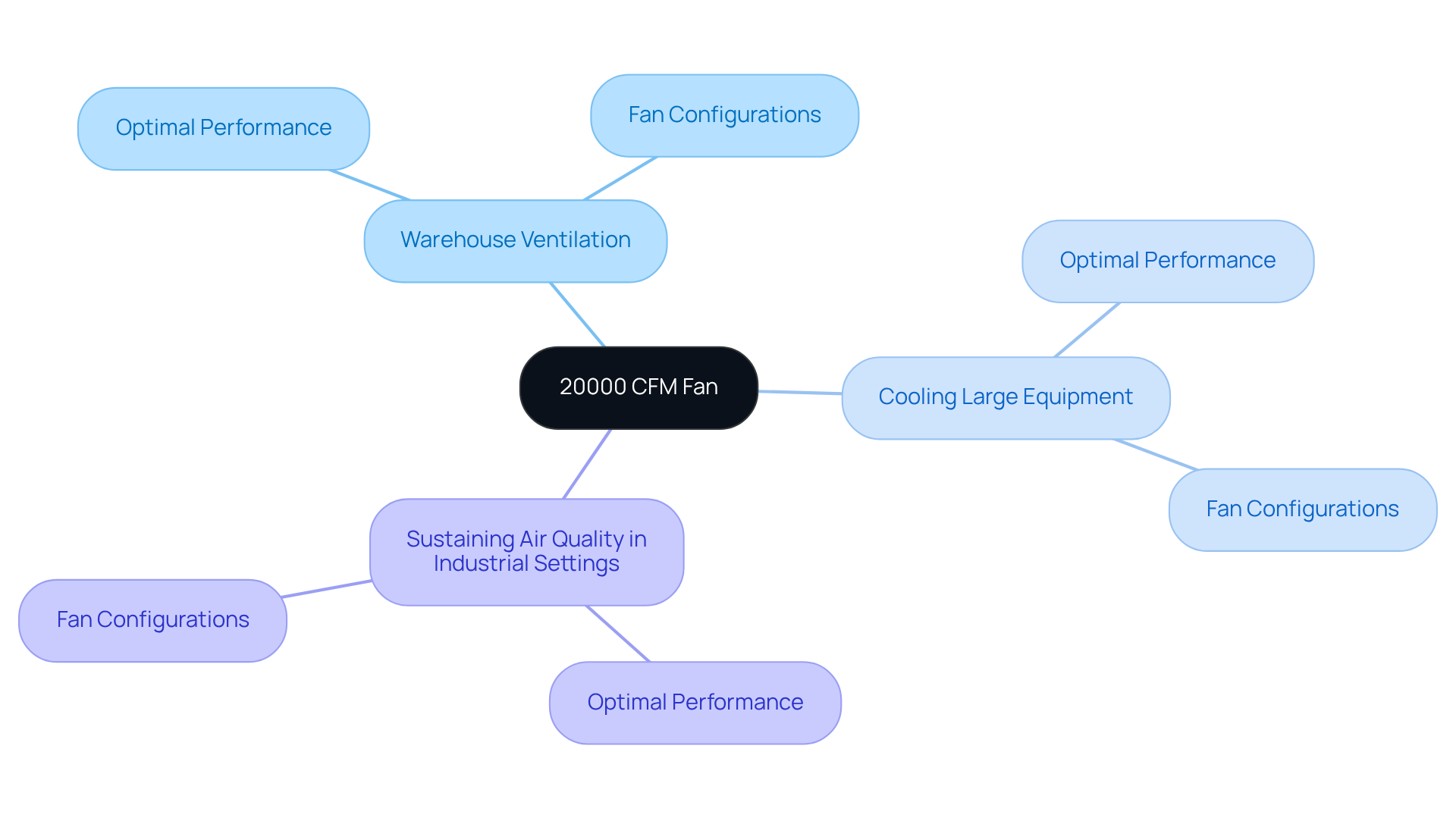

Versatility of Applications: Utilizing 20000 CFM Fans Across Industries

The 20000 cfm fan is versatile and can be utilized across various sectors, including production, agriculture, and commercial environments. Their capacity to move substantial volumes of air with a 20000 cfm fan renders them ideal for applications such as:

Engineers must evaluate the specific requirements of their applications to determine the most appropriate fan configurations and features, ensuring optimal performance and efficiency.

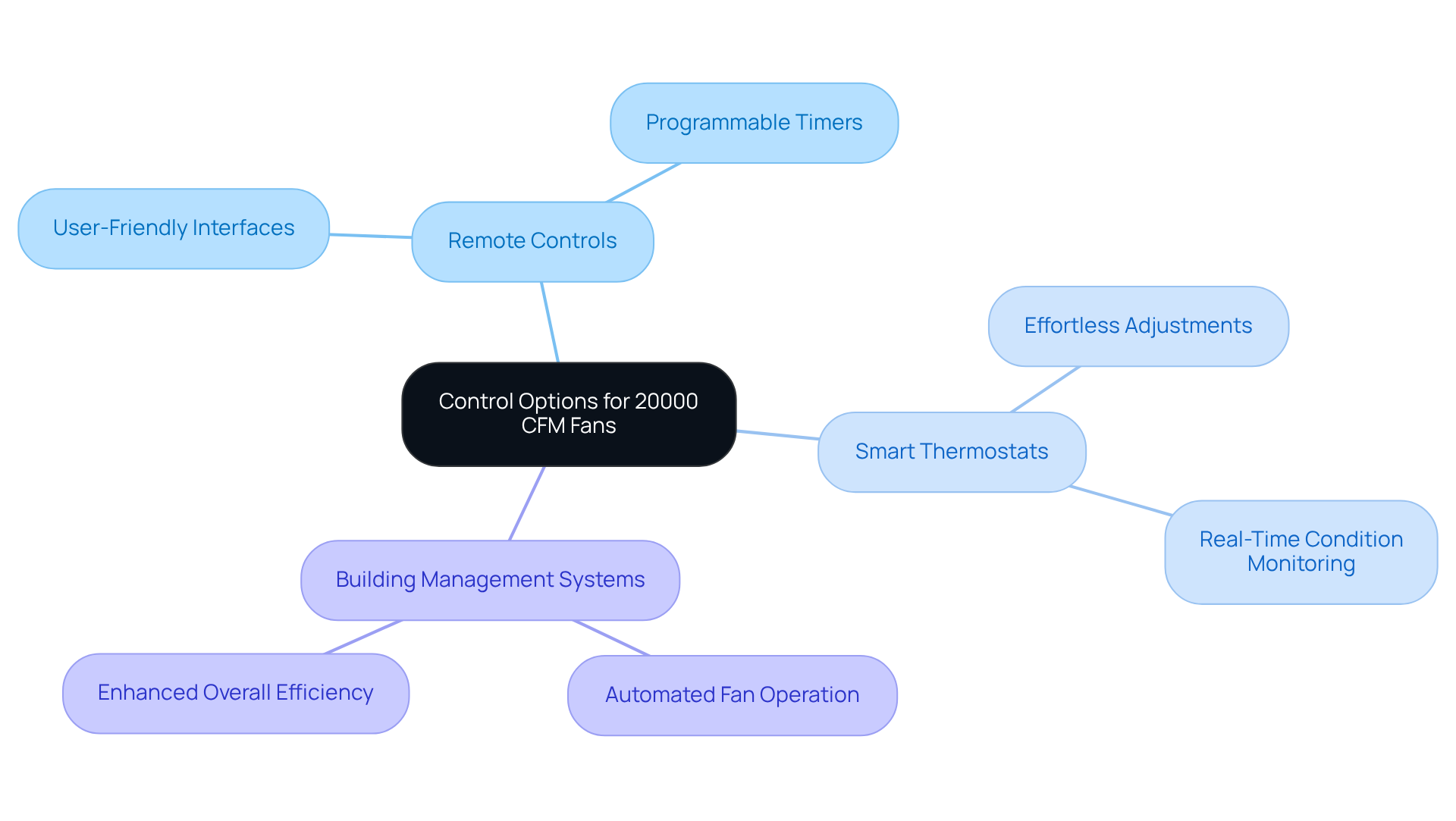

Control Options: Enhancing User Experience with 20000 CFM Fans

Sophisticated for the 20000 cfm fan are essential for enhancing user satisfaction. By integrating:

- Remote controls

- Smart thermostats

- Building management systems

precise airflow management becomes achievable. Engineers must prioritize user-friendly interfaces that facilitate effortless adjustments to fan settings, thereby ensuring optimal performance aligned with real-time conditions. Furthermore, the implementation of programmable timers and sensors can automate fan operation, significantly enhancing overall efficiency.

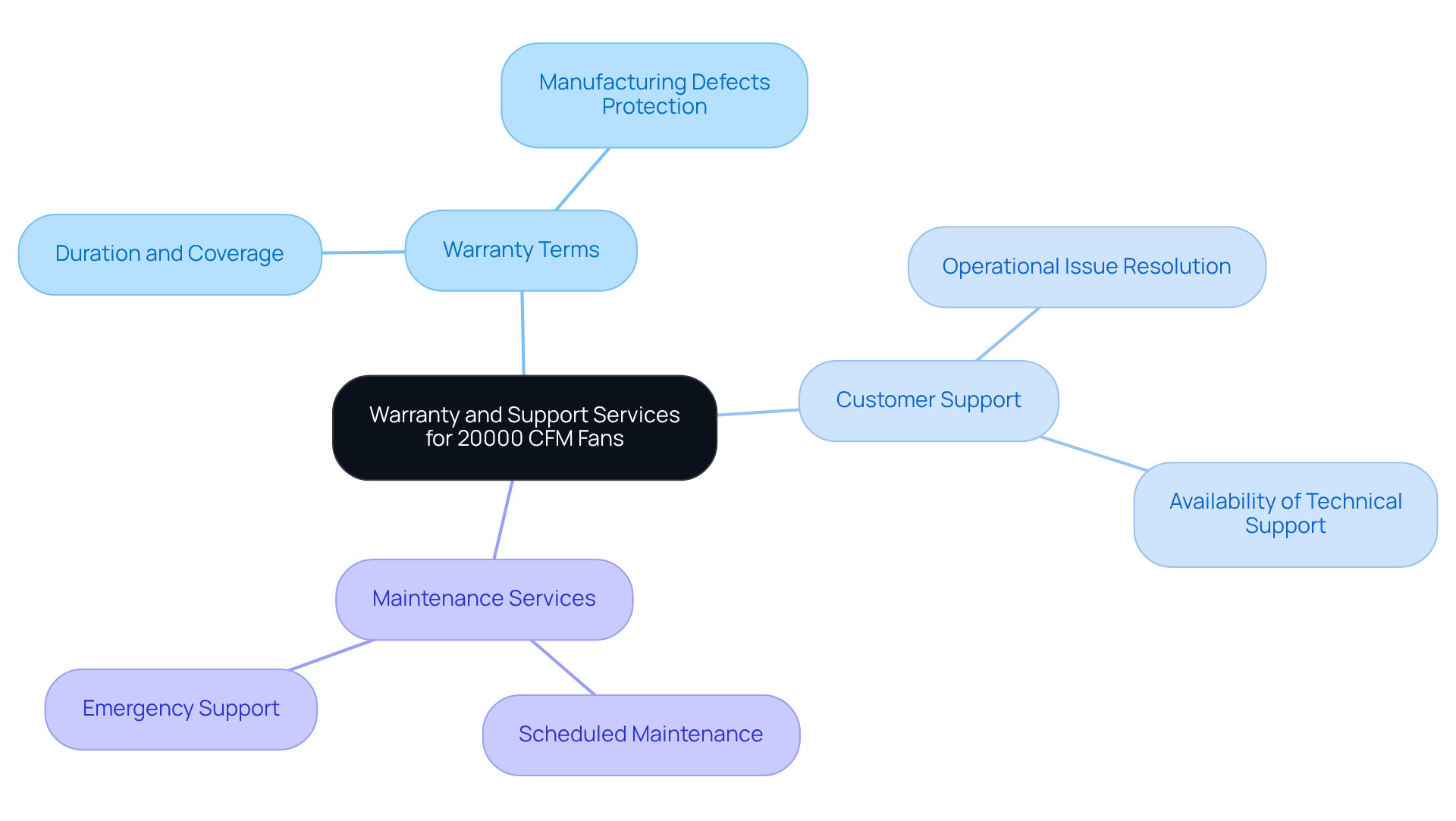

Warranty and Support Services: Ensuring Reliability for 20000 CFM Fans

When selecting a 20000 cfm fan, engineers must prioritize products that offer . A robust warranty not only safeguards against manufacturing defects but also instills confidence in users. Moreover, dependable customer support is crucial for resolving any operational issues that may arise. Engineers should actively inquire about the warranty terms, including duration and coverage, alongside the availability of technical support and maintenance services.

Conclusion

The exploration of 20,000 CFM fans underscores their critical role in enhancing ventilation and thermal management across various industries. These high-capacity fans are not only vital for efficient airflow but also embody advanced technologies that significantly improve energy efficiency, durability, and user safety. Understanding the essential features of these fans equips engineers with the knowledge necessary to optimize performance and effectively address specific operational challenges.

Key insights discussed include the importance of:

- airflow efficiency

- noise reduction

- material quality

Strategies such as:

- utilizing high-efficiency motors

- implementing variable frequency drives

- selecting durable materials like stainless steel and aluminum

play a significant role in enhancing the overall functionality of these fans. Furthermore, integrating safety features and ensuring ease of installation and maintenance are paramount for maximizing the lifespan and reliability of ventilation systems.

Ultimately, the significance of selecting the right 20,000 CFM fan extends beyond mere functionality; it encompasses energy savings, user satisfaction, and adherence to safety standards. Engineers are encouraged to leverage the insights provided to make informed decisions that not only enhance operational efficiency but also contribute to sustainable practices within their respective industries. By prioritizing these essential features, organizations can ensure optimal performance and reliability in their ventilation systems, paving the way for innovative cooling solutions.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in delivering innovative cooling solutions tailored for high-capacity systems, particularly in the electronics industry.

How does Gagner-Toomey Associates enhance ventilation and thermal management?

They collaborate with leading manufacturers to provide engineers with access to cutting-edge technologies that significantly improve ventilation and thermal management.

What is the importance of advanced cooling technologies in high-capacity systems?

Advanced cooling technologies elevate performance, enhance energy efficiency, and promote sustainability across diverse applications.

What factors are important for maximizing airflow efficiency in 20000 CFM fans?

Key factors include optimizing blade design, motor selection, and placement, as well as considering blade pitch, diameter, and material to enhance air movement and minimize turbulence.

How can variable frequency drives (VFDs) improve fan efficiency?

VFDs allow for the adjustment of fan speed based on demand, significantly improving overall efficiency.

What maintenance practices are vital for sustaining optimal air movement performance?

Regular maintenance and cleaning of fan components are essential for sustaining optimal air movement performance over time.

What strategies can be implemented to ensure quiet operation in 20000 CFM fans?

Strategies include prioritizing blade design, motor selection, and installation methods, as well as utilizing larger, slower-spinning blades and integrating sound-dampening materials and vibration isolation mounts.

Why are regular maintenance checks important for noise levels in fans?

Regular maintenance checks help identify and rectify issues that could lead to increased noise levels, ensuring optimal performance while minimizing disruptive sounds.