Overview

The article provides a comprehensive overview of the various types of industrial centrifugal blower fans that are essential for engineers, emphasizing their specific applications and benefits. It meticulously details nine distinct types, including backward inclined, forward curved, and variable speed blowers, offering valuable insights into their efficiency, performance characteristics, and suitability for diverse industrial needs. This information serves to guide engineers in selecting the appropriate fan for their specific applications.

Introduction

As the demand for energy-efficient solutions continues to rise across various industries, the importance of industrial centrifugal blower fans becomes increasingly evident. These adaptable devices are essential for optimizing airflow and enhancing performance in applications that span HVAC systems to industrial ventilation.

Engineers face the complex task of selecting the appropriate fan type, making it crucial to understand the distinct features and advantages of various centrifugal blower fan designs. What challenges may emerge when identifying the ideal fan for specific operational requirements, and how can engineers effectively navigate these considerations?

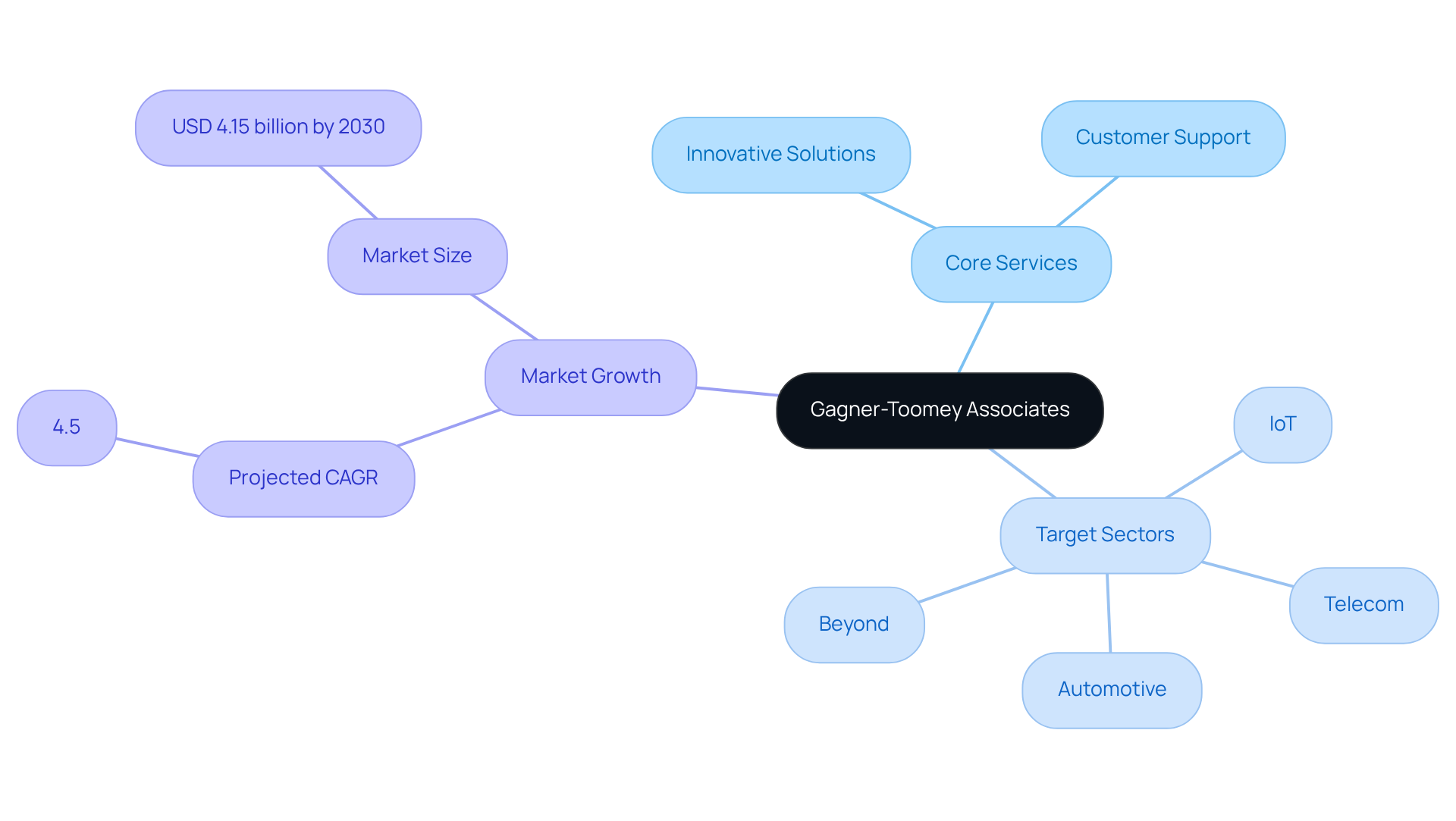

Gagner-Toomey Associates: Leading Provider of Industrial Centrifugal Blower Fans

Gagner-Toomey Associates stands as a leading supplier of industrial centrifugal blower fan systems, dedicated to delivering innovative solutions specifically tailored for the electronics sector. This commitment to exceptional customer support forms a cornerstone of their culture, ensuring engineers have access to cutting-edge technologies that significantly boost performance and efficiency across a multitude of applications. With a wealth of experience and industry knowledge, Gagner-Toomey represents a diverse portfolio of manufacturers, poised to meet the needs of engineers in sectors such as:

- Telecom

- IoT

- Automotive

- Beyond

As the radial fan market is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2025 to 2030, ultimately reaching a market size of USD 4.15 billion by 2030, Gagner-Toomey’s focus on customer service and product representation positions them as a dependable partner in navigating this evolving landscape. The organization’s successful applications of industrial centrifugal blower fans illustrate their ability to address the increasing demand for energy-efficient and high-performance solutions, in line with the sector’s shift towards sustainability and innovation.

Moreover, Gagner-Toomey plays a crucial role in linking engineers with local distribution partners, ensuring a consistent supply of components precisely when and where they are needed.

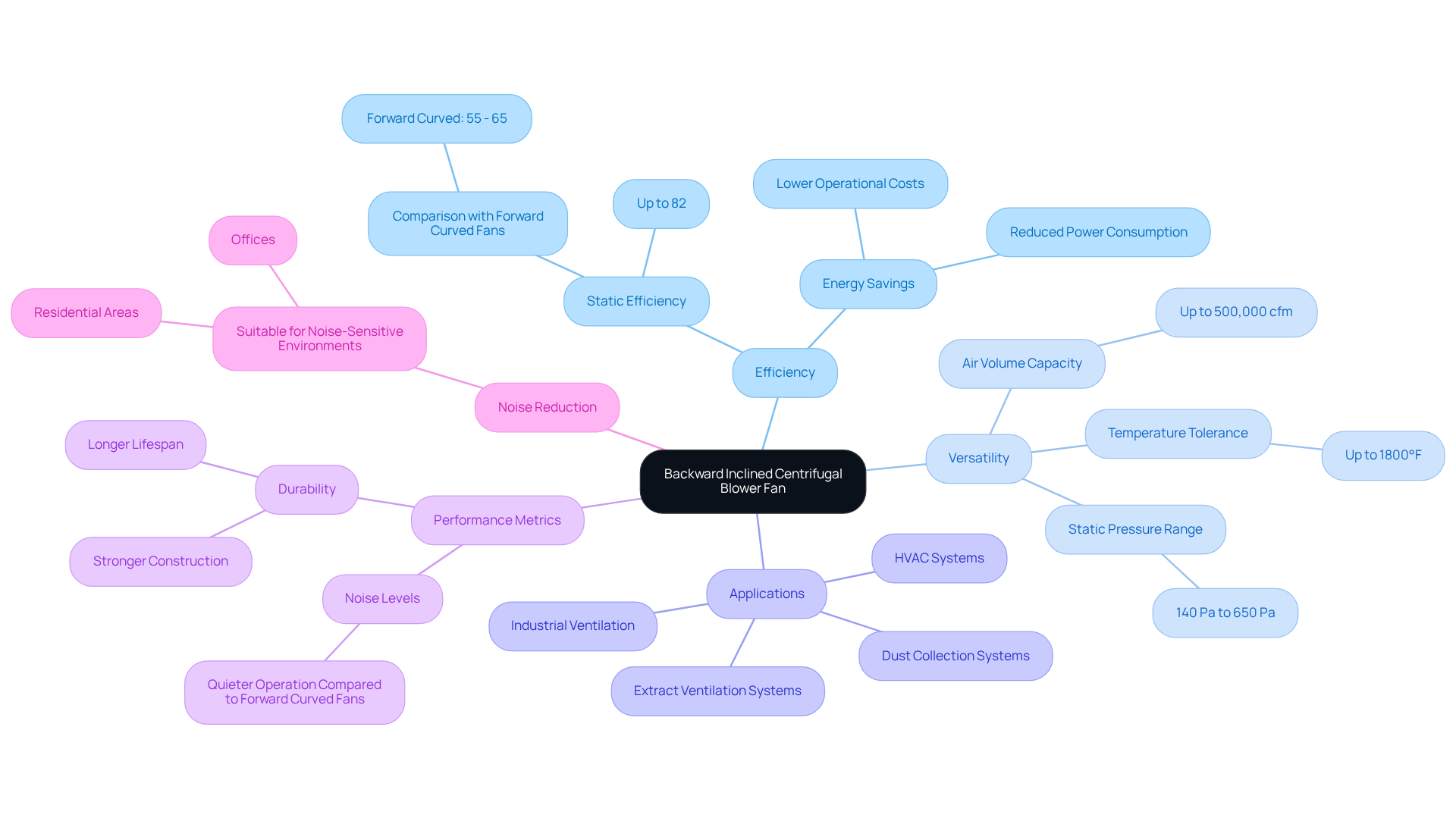

Backward Inclined Centrifugal Blower Fan: Efficiency and Versatility

Backward inclined centrifugal blower units from Gagner-Toomey Associates are engineered with blades that curve away from the direction of airflow. This design results in enhanced efficiency and reduced energy consumption. The industrial centrifugal blower fan units are particularly effective in applications that require consistent airflow against varying static pressures, capable of managing static pressure values from 140 Pa to 650 Pa. This makes industrial centrifugal blower fans ideal for and industrial ventilation. Their robust construction minimizes turbulence and noise, thereby enhancing overall performance and ensuring reliability in demanding environments.

Backward inclined blowers can operate at temperatures reaching 1800°F and achieve static efficiencies of up to 82%, leading to significant energy savings. They are capable of handling volumes up to 500,000 cfm, making the industrial centrifugal blower fan especially effective in industrial settings such as printing presses and dust collection systems, where it efficiently manages air quality and operational costs. Moreover, their quieter operation compared to forward curved devices makes them suitable for noise-sensitive environments, and they excel in extract ventilation systems aimed at eliminating pollutants.

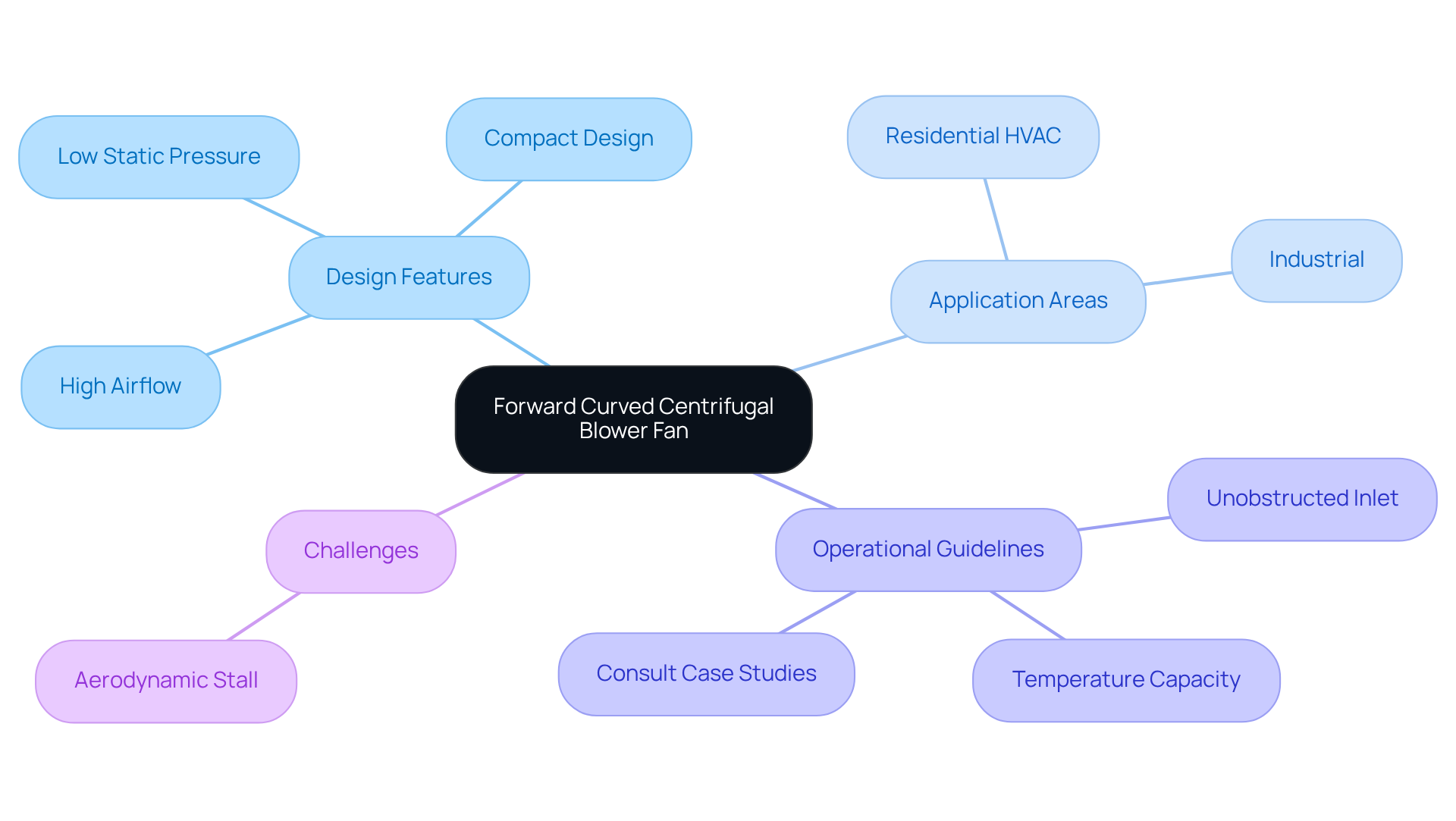

Forward Curved Centrifugal Blower Fan: High Airflow and Compact Design

Forward curved centrifugal blower units are engineered with blades that bend in the direction of airflow, enabling them to deliver substantial volumes of air at low static pressures. Their compact design proves advantageous in situations where space is at a premium, such as in residential HVAC systems and smaller industrial environments. These devices thrive in low-pressure settings, rendering them ideal for diverse ventilation needs while ensuring quiet operation. With the ability to handle , forward curved blowers play a pivotal role in effective air circulation across both commercial and residential spaces, significantly enhancing air quality and comfort.

It is critical to ensure that the inlet side of the fan remains unobstructed within a distance of 1/3 of the fan diameter from the inlet to sustain optimal airflow efficiency. Furthermore, these units are capable of operating in environments with temperatures reaching 1800°F, making them versatile for various applications. Engineers must also be mindful of the potential challenges that arise when selecting forward curved blowers for low pressures and high volume flow, as this may lead to aerodynamic stall.

For practical guidance, engineers are advised to consult case studies that address the selection of forward curved pumps based on system pressures and volume flow requirements. This approach will empower them to make informed decisions tailored to their specific operational needs.

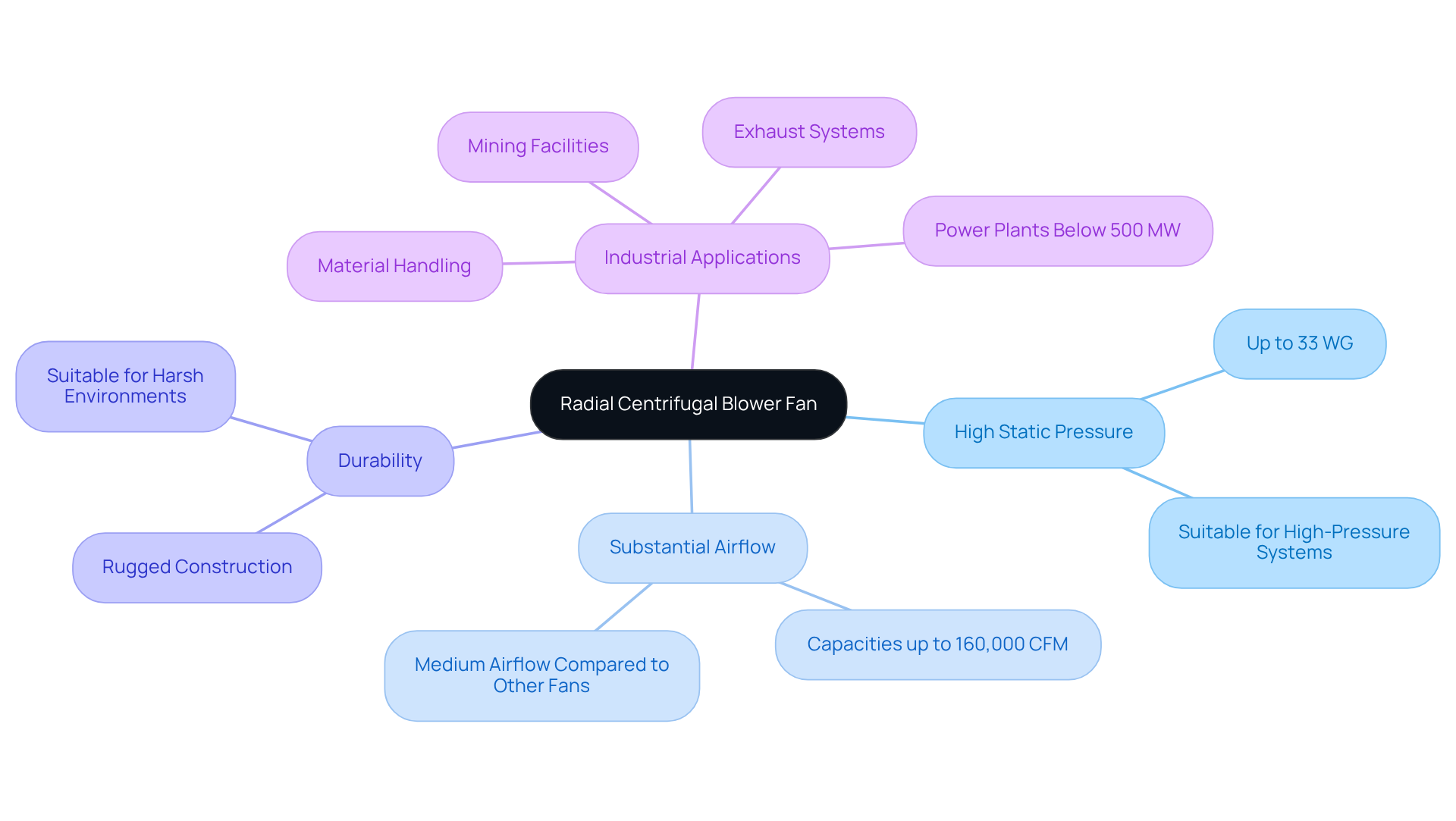

Radial Centrifugal Blower Fan: Robust Performance for Heavy-Duty Applications

Radial air-moving devices are engineered for heavy-duty applications, adept at generating high static pressures while ensuring substantial airflow. With their straight blades extending radially from the center, are particularly suited for industrial processes demanding robust performance, such as material handling and exhaust systems. Their efficiency shines in environments where durability and reliability are paramount, assuring consistent performance even under challenging conditions.

In summary, the design and functionality of radial air-moving devices make them indispensable in various industrial applications, underscoring their role in enhancing operational efficiency.

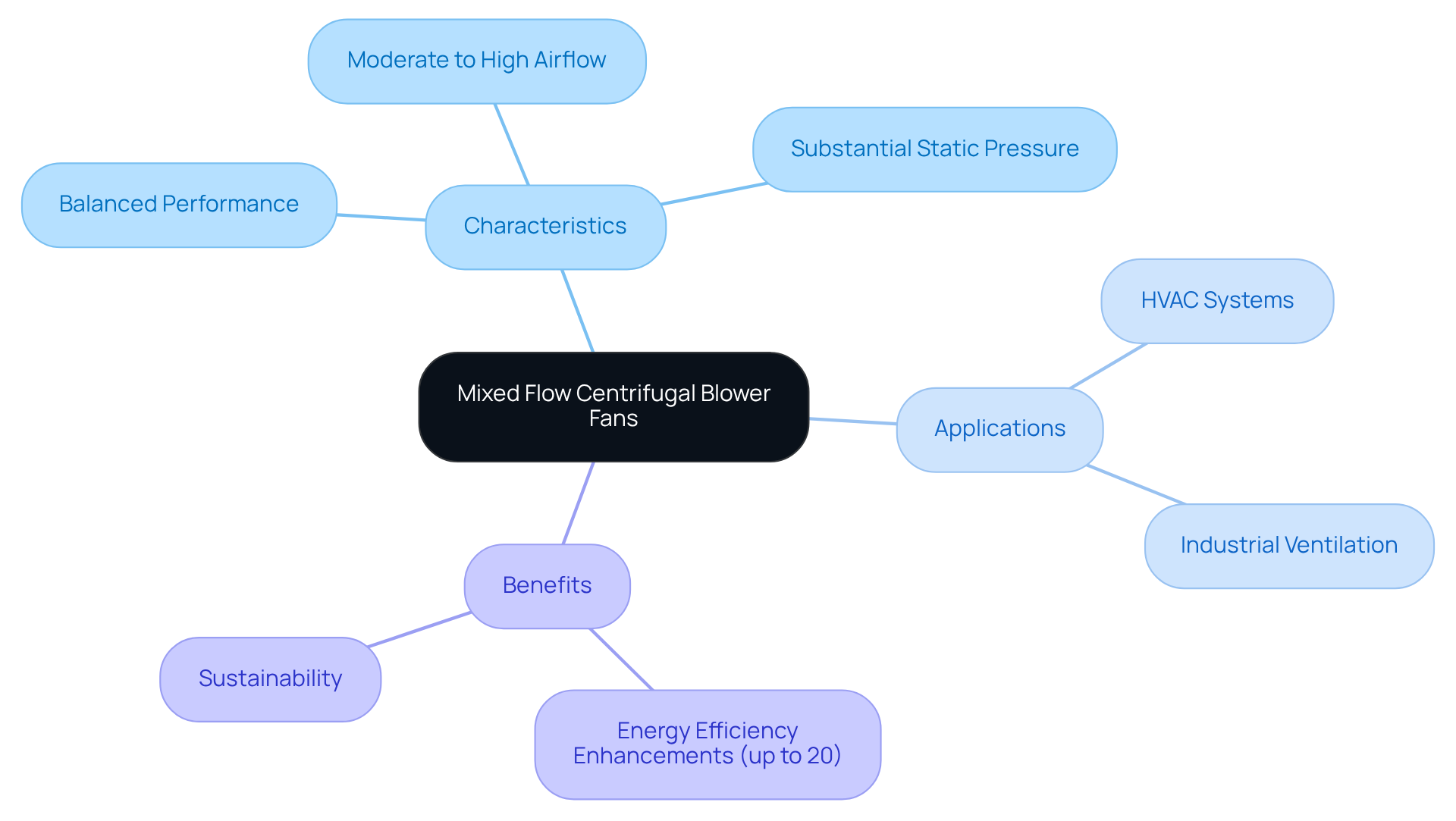

Mixed Flow Centrifugal Blower Fan: Balanced Performance and Efficiency

Mixed flow rotary ventilators uniquely combine the characteristics of axial and rotary types, providing balanced performance and efficiency. These devices excel in managing moderate to high airflow rates while generating substantial static pressure, making them ideal for various applications, particularly in HVAC systems and industrial ventilation.

Gagner-Toomey Associates, the world’s largest manufacturer of standard and custom air-movers, offers a comprehensive range of DC input centrifugal blowers, available in sizes from 15 to 225mm, with IP protection available upon request. Their innovative designs not only facilitate quieter operation but also contribute to , reflecting the current emphasis on sustainability.

For instance, studies indicate that utilizing mixed flow devices can result in energy efficiency enhancements of up to 20%, making them an appealing option for engineers. As engineers pursue adaptable solutions, mixed flow devices stand out as a remedy that effectively addresses both performance and environmental considerations.

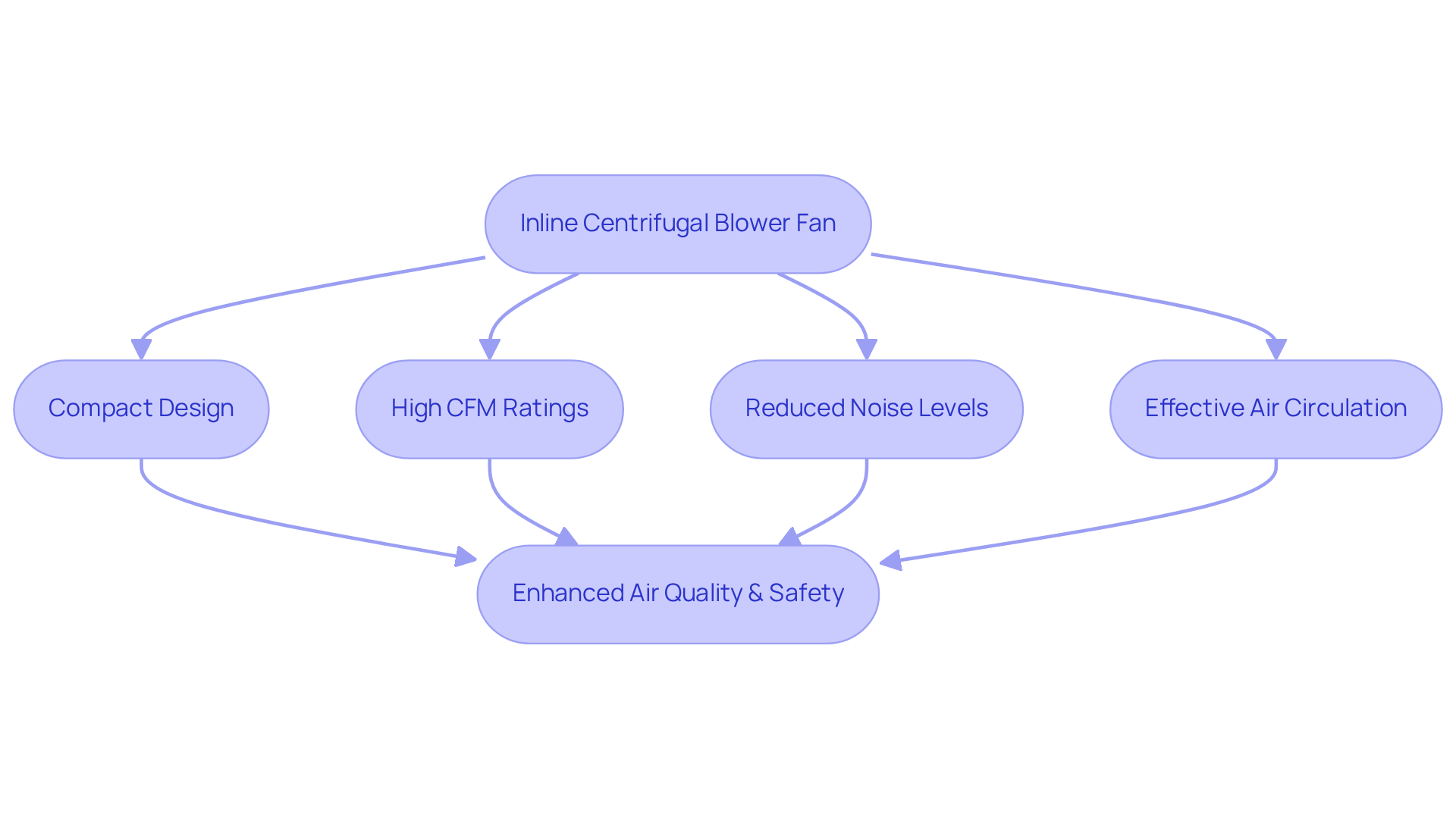

Inline Centrifugal Blower Fan: Space-Saving Solutions for Industrial Needs

Inline blowers are engineered for seamless integration into duct systems, delivering effective air circulation in space-constrained environments. Their compact design simplifies installation in confined spaces, making them particularly well-suited for exhaust systems and air conditioning units. Typically, inline devices boast , often surpassing 5 ft for optimal operation, thereby enhancing their efficiency in air movement. These devices excel at maintaining consistent airflow while significantly reducing noise levels; notably, they operate more quietly than traditional inline systems, especially at high speeds, which is crucial for achieving optimal performance in both residential and industrial applications.

In industrial settings, the industrial centrifugal blower fan plays a vital role in ensuring effective ventilation and air quality management, contributing to a safer and more comfortable working environment. As emphasized, air circulation is paramount in industrial contexts, highlighting the importance of the industrial centrifugal blower fan in enhancing air quality and safety.

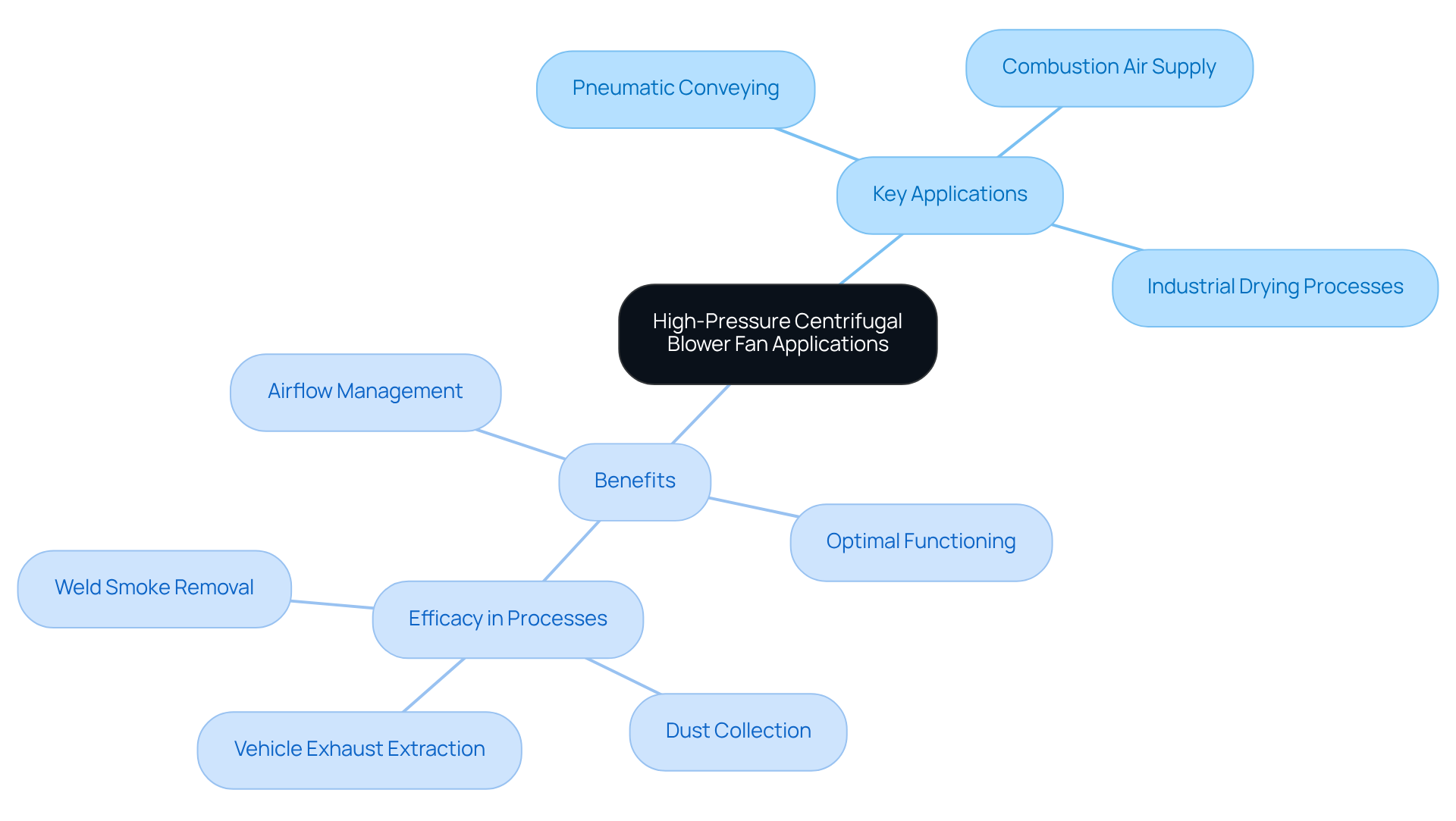

High-Pressure Centrifugal Blower Fan: Ideal for Demanding Applications

High-pressure industrial centrifugal blower fan units are expertly engineered to deliver substantial airflow while effectively overcoming significant resistance within duct systems. These industrial centrifugal blower fans are particularly adept in applications such as:

- Pneumatic conveying

- Combustion air supply

- Industrial drying processes

Their robust construction, combined with an efficient design, ensures that the industrial centrifugal blower fan delivers reliable performance even in the most demanding environments. Recent updates in 2025 underscore the importance of maintaining these devices for optimal functioning, as they are crucial for enhancing system efficiency and reducing operational costs. For instance, pressure fans demonstrate exceptional efficacy in processes like:

- Dust collection

- Weld smoke removal

- Vehicle exhaust extraction

showcasing their versatility across various industrial applications. With , these devices can significantly improve airflow management, ensuring that industrial operations run smoothly and effectively.

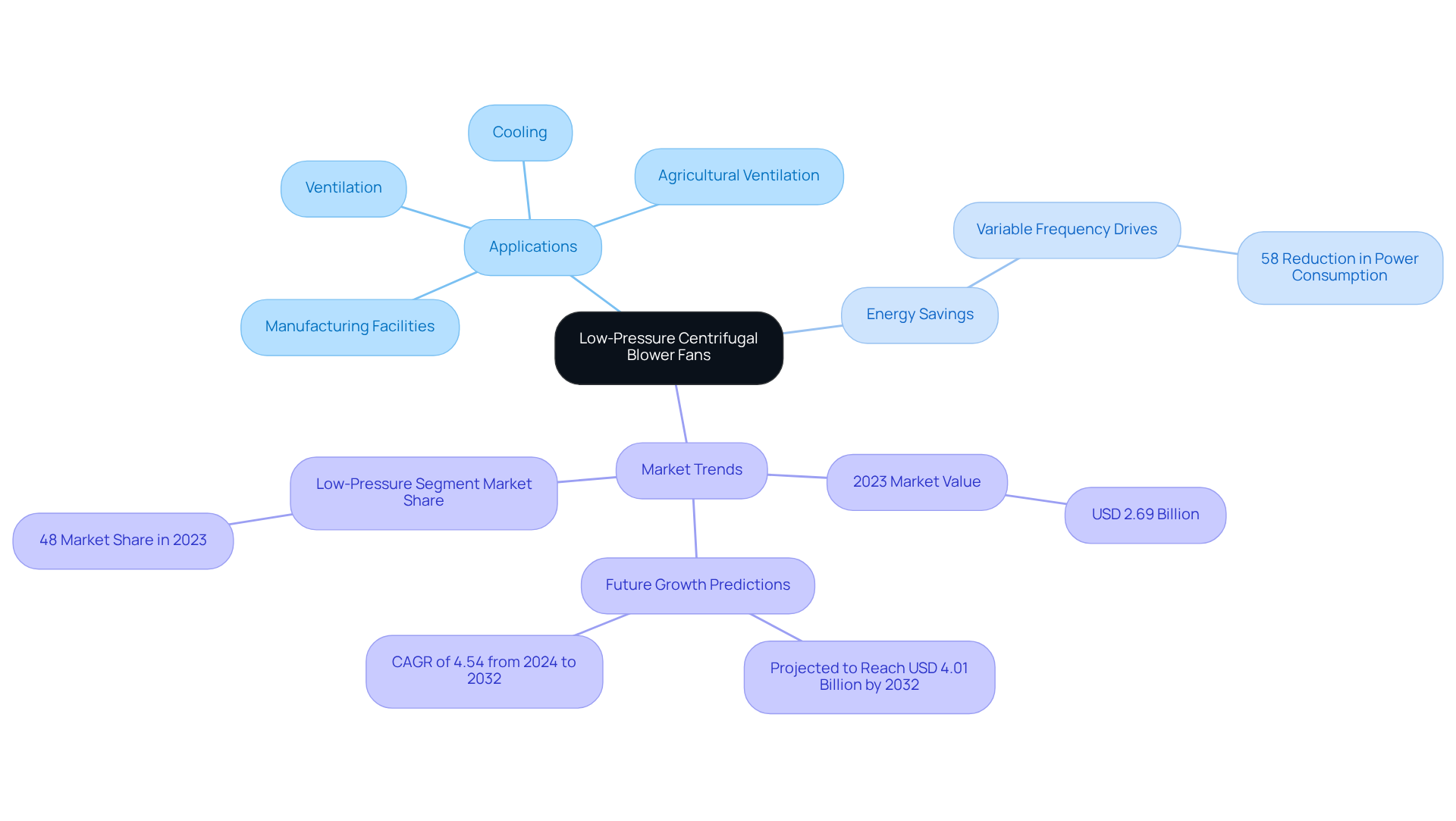

Low-Pressure Centrifugal Blower Fan: Optimal for High Air Volume Applications

Low-pressure industrial centrifugal blower fan units are meticulously engineered to transport substantial volumes of air at relatively low pressures, making them particularly suitable for applications like ventilation and cooling in expansive industrial environments. These industrial centrifugal blower fans are particularly effective in agricultural ventilation systems and large manufacturing facilities, where high airflow is essential without the requirement for excessive pressure. Their design not only guarantees optimal performance in high-volume scenarios but also facilitates significant energy savings.

For example, the implementation of variable frequency drives (VFDs) can result in a remarkable 58% reduction in power consumption by tailoring airflow to meet operational demands.

The radial fan market was valued at USD 2.69 billion in 2023 and is anticipated to reach USD 4.01 billion by 2032, with the low-pressure segment leading the market, commanding over 48% of the market share in 2023. This rising demand for is propelled by their capacity to enhance air quality and reduce operational costs across various sectors.

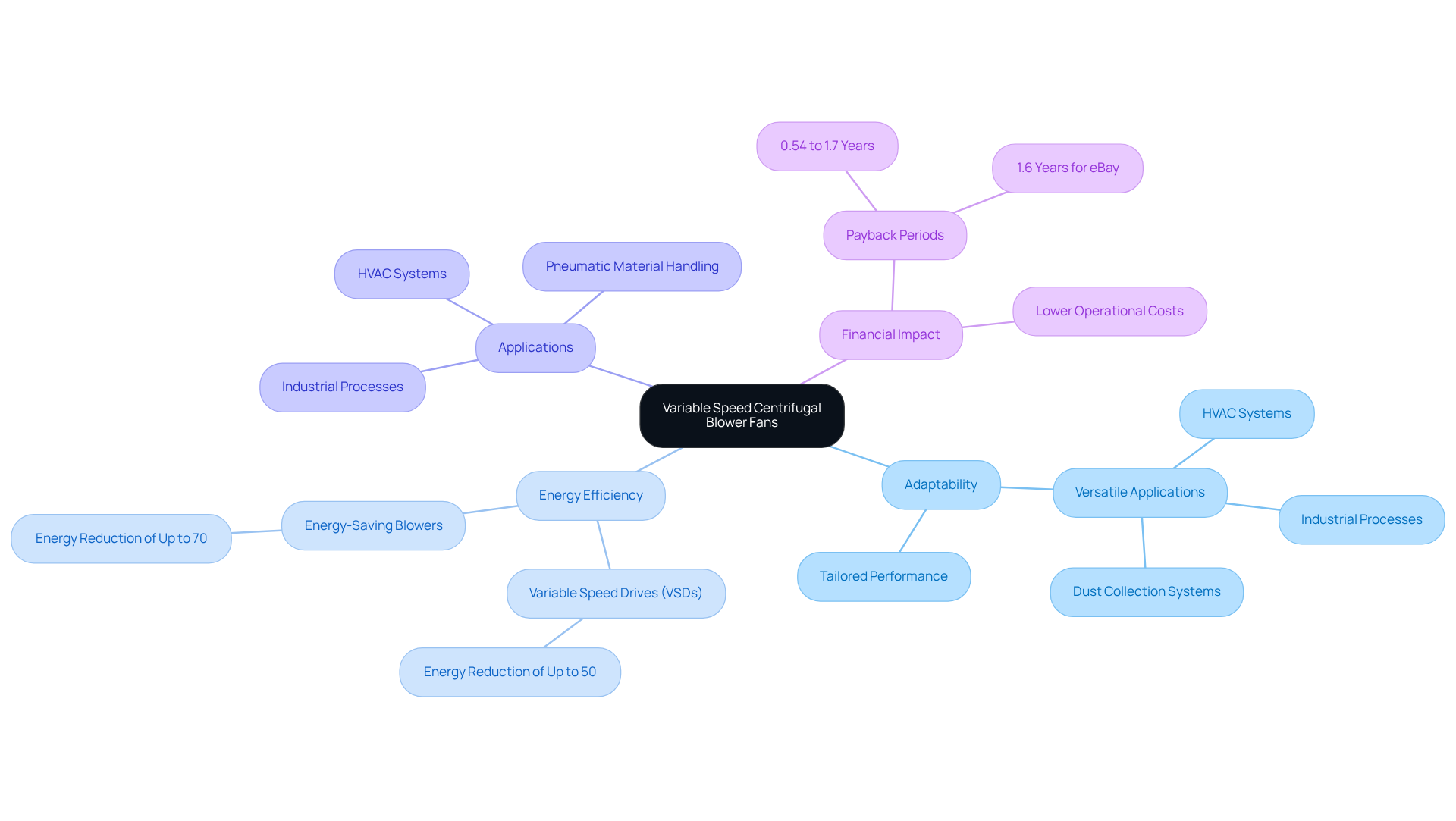

Variable Speed Centrifugal Blower Fan: Adaptable Solutions for Dynamic Needs

Variable speed centrifugal blower units offer , enabling precise control over air movement tailored to system requirements. By adjusting their speed to meet varying load demands, these devices significantly enhance energy efficiency and reduce operational costs. For instance, employing variable speed drives (VSDs) can lead to energy usage reductions of up to 50% in specific contexts, while energy-saving blowers can decrease energy consumption by as much as 70% compared to conventional AC motors. Their versatility positions them as ideal solutions for a wide range of applications, particularly in HVAC systems and industrial processes, where maintaining optimal airflow is critical for both performance and comfort.

In practical applications, facilities utilizing VSDs have reported substantial savings, with payback periods for installations typically ranging from 0.54 to 1.7 years. A notable example is eBay, which documented a 1.6-year payback for VSD retrofits at their Phoenix data center, underscoring the financial advantages of these advanced technologies. Furthermore, as energy costs continue to rise and traditional cooling systems contribute significantly to environmental challenges, the importance of such efficient solutions becomes increasingly evident. This makes variable speed rotary air movers, such as industrial centrifugal blower fans, an essential component in modern industrial environments.

Choosing the Right Centrifugal Blower Fan: Key Considerations for Engineers

When selecting an industrial centrifugal blower fan, engineers must consider several critical factors, including , static pressure, energy efficiency, and application-specific needs. Airflow, typically measured in cubic feet per minute (cfm), is essential; comprehending the operational environment and specific system demands will guide the selection process effectively. Under ideal conditions, industrial air movers can achieve performance levels exceeding 80%, with power loss during peak efficiency remaining below 1%. This underscores the importance of energy efficiency in the selection process.

Moreover, assessing the fan’s construction—particularly materials that resist corrosion and moisture—is vital for ensuring longevity, especially in harsh environments. Sound levels are also significant; while certain rotary blowers may produce considerable noise, quieter models are available to minimize disruption in sensitive applications. Furthermore, additional insulation can further reduce noise levels.

Maintenance requirements differ by fan type. Regular inspections, including cleaning blades and monitoring for dust accumulation, are crucial for sustaining optimal performance. A notable case study highlighted that consistent maintenance extends the lifespan of industrial centrifugal blower fans and ensures reliable operation. Engineers should also explore customization options, as many manufacturers offer fans tailored for specific applications, thereby enhancing effectiveness.

Advancements in fan technology, particularly smart controls for performance monitoring, are projected to gain importance by 2025. These innovations facilitate real-time adjustments and alerts, optimizing fan operation further. By thoroughly evaluating these factors, engineers can make informed decisions that align with their specific application needs, ensuring efficient and effective airflow management.

Conclusion

The exploration of industrial centrifugal blower fan types underscores their critical role in enhancing efficiency and performance across various engineering applications. Each fan type, from backward inclined to variable speed, presents unique advantages tailored to meet specific operational needs, thereby emphasizing the necessity of selecting the right system for optimal results.

Key insights reveal the efficiency of backward inclined fans in managing static pressure, the compact design of forward curved fans for space-saving solutions, and the robust performance of radial fans in heavy-duty applications. Furthermore, mixed flow and inline fans offer balanced performance and seamless integration into existing systems, while high-pressure and low-pressure fans address diverse industrial requirements. The significance of variable speed fans in adapting to dynamic needs further highlights the evolving nature of blower technology.

In conclusion, engineers must carefully consider the specific needs of their applications when selecting centrifugal blower fans. By comprehensively understanding the unique features and benefits of each type, alongside the importance of maintenance and efficiency, informed decisions can be made that not only enhance operational performance but also contribute to sustainability efforts within their industries. The growing market demand for energy-efficient solutions serves as a poignant reminder of the pivotal role these systems play in modern engineering practices.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in providing industrial centrifugal blower fan systems, particularly for the electronics sector, focusing on innovative solutions and exceptional customer support.

Which industries does Gagner-Toomey serve?

Gagner-Toomey serves various industries, including Telecom, IoT, Automotive, and others.

What is the projected growth rate for the radial fan market?

The radial fan market is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2025 to 2030, reaching a market size of USD 4.15 billion by 2030.

What advantages do backward inclined centrifugal blower fans offer?

Backward inclined centrifugal blower fans are designed for enhanced efficiency and reduced energy consumption, capable of managing static pressure values from 140 Pa to 650 Pa, and can operate at temperatures up to 1800°F with static efficiencies of up to 82%.

In which applications are backward inclined blowers particularly effective?

They are particularly effective in HVAC systems, industrial ventilation, printing presses, and dust collection systems, where they manage air quality and operational costs efficiently.

How do forward curved centrifugal blower fans differ from backward inclined fans?

Forward curved centrifugal blower fans have blades that bend in the direction of airflow, allowing them to deliver high volumes of air at low static pressures, making them suitable for compact spaces and low-pressure ventilation needs.

What are some key considerations when using forward curved blower fans?

It is important to keep the inlet side unobstructed within a distance of 1/3 of the fan diameter to maintain optimal airflow efficiency. Engineers should also be cautious of potential aerodynamic stall when selecting these fans for low pressures and high volume flow.

What temperature can forward curved blower fans operate in?

Forward curved blower fans can operate in environments with temperatures reaching up to 1800°F.

How does Gagner-Toomey assist engineers in their projects?

Gagner-Toomey connects engineers with local distribution partners to ensure a consistent supply of components when and where they are needed.